As attention turns to the impending release of the National Shipbuilding Strategy, the term “virtual shipbuilding strategy” has gained traction after the Parker Report, but what exactly does it mean for industry and the navy?

The government is committed under the 2015 SDSR to publish a National Shipbuilding Strategy in 2017. Its aim is “to place UK naval shipbuilding on a sustainable long-term footing”. Initially scheduled for release with the 2016 Autumn statement, the strategy has now been rescheduled for Spring 2017. In its place, Sir John Parker, the independent chair of the strategy, released an intermit report of thirty-four recommendations that will inform the strategy in late 2016.

Parker is a naval architect by training and has previously served as the chairman of Babcock International and BVT Surface Fleet. He presently serves as the chairman of the mining firm Anglo American. He was knighted in 2001 for services to defence and shipbuilding and awarded the Grand Cross of the Most Excellent Order of the British Empire (GBE) in 2012 for services to the voluntary sector and industry.

The Virtual Shipbuilding Strategy (or VSb) is an industry model that captures the skills and talents of the number of regional shipyards across the UK. These shipyards have seen a resurgence of late and have demonstrated clear cost competitiveness and the capability to build fully outfitted “blocks” though the aircraft carrier alliance and their other orders. It therefore represents a shift away from the current BAE monopoly.

Shipyards highlighted in the report include; Cammell Laird Merseyside – currently holder of several long-term RFA refit contracts, Babcok Marine Appledore – currently working on OPVs for the Irish Navy, Babcock Marine Rosyth, Harland and Wolff Belfast, A&P Tyneside and Ferguson Marine Clyde. All have demonstrated clear capacity over recent years to win contracts against international competition by promoting innovation and cost effectiveness.

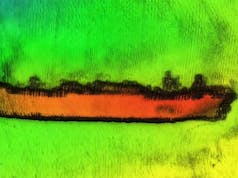

The basic core of VSb is the use of block based construction for the Type 31 frigates. Each shipyard would be allocated a share of the vessels, producing sections (or blocks) which are then transported to a central location and assembled into the final vessel. This style of construction was used internationally for the ten Anzac Class frigates in the 1990s, allowing New Zealand’s small shipbuilding industry to contribute to the overall class. In Britain, it was most notably used for the Queen Elizabeth class aircraft carriers.

By building blocks in series and in parallel the shipyards would be able to capture the learning curve productivity benefits. This benefit was less evident in the aircraft carrier project as only two vessels were constructed. Improvements in block construction would reduce construction time and cost. This would increase the possibility of the government exercising the additional vessels options to increase fleet size. It would also make the class more competitive on the international export market.

Contracts for the shipyards would be carefully crafted under VSb. They must be taut, and properly incentivise delivery through profit incentives that will enable future investment. Management would be incentivised to avoid cost growth, rather than simply passing it on to the customer.

The shipyards would also be required to develop “global competitiveness plans”. This allows for targeted investments in emerging technologies to modernise processes. The use of global competitiveness plans has already been successfully with Jaguar Land rover and Meyer Werft in Germany. It also serves to encourage and enable shipyards to generate additional revenue streams and not solely rely on MOD contracts.

While proposed initially for implementation with the Type 31 programme, the Parker report highlights how the benefits of VSb could improve long term shipbuilding options. For example, this could allow UK shipyards to become a competitive option for support ships, such as RFA stores vessels, to prevent those contracts continuing to go overseas.

The importance of this proposal is clear. There is no precedent for building two ‘first of class’ frigates in a single shipyard in the UK. Both vessels are critical assets with a time crucial delivery for both the navy and nation. Parallel construction on the same site risks potential complications and delays compromising construction of both vessels. By have a separate lead shipyard and/or alliance build the Type 31 the risks to the programme from the Type 26 build are reduced. This allows frigate numbers to be maintained and an exportable light frigate model to be established.

The political implications of this plan are significant. Up until the 2015 SDSR the BAE shipyards on the Clyde has been expected to build the then planned thirteen Type 26 Frigates. The introduction of the Type 31 concept, and particularly the VSb model, would see their workload reduced from building five full vessels to either the construction of blocks or the final assembly stage only. The resulting reduction in workload and likely jobs could further impact the already highly politicised Scottish shipbuilding industry. It could however have positive political implications across the country as regional shipyards would be able to sustain their size and potentially expand.

Is it me or has the much anticipated National Ship building strategy paper been quietly shelved and ignored- there is no new knews from the government or the MOD on how they are going to comply with the logical and sensible recommendations from the report. Seems HMG are going to just ignore it and continue with the perilous state of the RN (just 19 surface warships) What the RN needs asap is clear to everyone and anyone, who has even a slight interest in UK national defence: Replacement for HMS Ocean (or at least retain her until 2023 to buy… Read more »

Good point well made

You need a strategy to not build ships?

Pillock

No now kiddo…. play nice or mommy will give you a spanking!

Weird too

At the risk of sounding like a broken record, no national shipbuilding strategy can survive without a 50 year timescale and a good plan of volume. Why 50 years? Well that is due to the lifecycle of the carriers and also constitutes 2 nuclear reactor lifecycles for the Subs, it also gives industry time to plan and invest. Lastly it gives everyone time to even out the build into a manageable yearly cost. I am also a big fan of splitting the strategy into 4 components Major surface combatants Surface Support Submarines Small vessels (less than 30m) My proposed 50… Read more »

Great comment

Note that there are no OPV’s, No Minesweepers and no dedicated Amphibious craft in this proposal. OPV’s are not value for money (IMO), especially when we are short of fighting craft. The Karel Doorman class of JSS used by the Dutch can easily take 6 Merlins or 2 chinook as well as acting as a solid stores supply ship – a bit of work on 4 to bring in docks and you have a multi purpose asset that can conduct a large number of roles (inc. hospital) Mine hunters will be replaced by Type31’s with Arcims, thats the future its… Read more »

Although I like your posts they depress me a bit because I keep thinking “if only”. A properly funded, well thought out long term plan such as your suggestion that allowed a proper drumbeat for construction, without all these slowdowns and delays in builds that add so much wasted cost (e.g. the > £1bn added to carrier costs because of the slowing of the build schedule), could get us so much more than we have now. In fact I think your figures might under-estimate the benefits to be had from a proper drumbeat being maintained. £25bn for 20 SSN over… Read more »

Julian It is depressing unfortunately we have got into the habit of costly life extension programmes that seem good value but really are not. Some of these ships are getting £100m refits every 10 years which is just wasteful. Build them and run them into the ground – the last 5 years of an escorts life should be spent on anti drugs or constabularly duties and the latest ship should be put into the front line defensive/offensive roles. With 40 escorts you will have the ability to build consistently and cycle them through to less demanding roles as they get… Read more »

Pac-Man

Nice concept but Westminster is in a bubble .

Would be great to see a fleet again

So this Treasury (not MoD, not MoBusiness) strategy boils down to laying off the only workers in the UK skilled enough to build complex warships like frigates & destroyers, and giving their work to a bunch of box builders so they can learn how to build frigates in bits and pieces? Then expensively transport the bits to an assembly site where hopefully they all fit. Got winner written all over it. NOT. Parker worked at Appledore and BVT, his report recommends giving them work at the expense of Bae. What a surprise. British stupidity at it’s finest. Take a look… Read more »

Virtual Ship Building is what we have now. There really is a complete lack of imagination and drive here. I believe we are at a crucial moment in defence with the revolution in electronics and AI making this era as significant as the advent of gunpowder. It really pains me to read that the Admiralty has been mulling over a new frigate design of what, eighteen years? If this is anywhere near true then it is a complete disgrace. I really do question the quality of our national leadership and those in uniform seemingly more intent on advancement than the… Read more »

Hi Barry 18 Years is optimistic – probably longer and yes it is a disgrace. It gets worse the more you know about it actually, the carriers is just laughable but will turn out to be groundbreaking I believe, Astutes are world class after we got a set of Americans in to tell us how to build them efficiently. Where we are really lacking is in escorts as the French and Germans are light years ahead of us. Take a look at FREMM or the MEKO class – never mind the new French FTI/Belharra. The key here is lack of… Read more »

Thank you pacers. The late Professor Anthony King, who has just passed away, cited the U.S.M.C. as a possible model for Britain’s armed forces two or three elections back (King was a politics prof.) and I believe he was correct. More shocking news today regarding our now somewhat defunct submarine ‘fleet’. I believe the Astute business was down to not having built any nuclear submarines in something like twenty years! Armchair critic or not, I think even I could do better than this present mob in Whitehall and I willingly forgo the usual gong for failure!

I agree that it’s tragic how many expensive twists and turns and periods of completely standing still we seem to have on the way to an end result, e.g. carriers and Astutes as you mention. Even though the end result is often very, very good, again e.g. carriers (probably) & Astute, they end up costing us way more than they should have and arriving years later than they could have. I think T26 (if it ever arrives) will be another to add to the examples just listed. I have reasonably high hopes that it will be significantly better and more… Read more »

In truth I think the National Shipbuilding report misses an opportunity. As stated above I think we could have enough work to sustain 4 yards with proper fleet management and scheduling: Complex Warships To be built in Scotland (subject to assurance on staying within the union) – otherwise Camel Laird (8 per 5 years) All Support and small ships fleet to be built at Camel Laird (4 support and 85 small craft per 5 years) Subs at Barrow (3 per 5 years) Surface fleet maintenance should be conducted out of Devonport. This places all of our shipbuilding on the west… Read more »

If I was Defence Minister I would implement a ship building strategy that would be very difficult for my successors to cut away at in the future. Sir John’s suggestion of having several yards all capable of building ship blocks means that someone can cut ship numbers and close a yard. I would ships built in a configurable way in a yard for building big hulls or a different yard for building small ones. Then Devonport and Portsmouth would fit out each hull with sensors and weapons in which ever configuration is needed. They would also do the mid-life re-fits… Read more »

Couldnt agree more Tim, We closed Devonport dock (frigate factory) after a major upgrade – your idea of weapons fit out at Portsmouth is fantastic and very logical, and on T45 if we have fixed the propulsion issues we should then put this into the T26 class as my understanding is that it is 30% more fuel efficient than normal propulsion systems. What is the point in building somehting cutting edge if we dont then learn from it and move it into other classes when it is mature and all the problems are resolved. I think we have to spread… Read more »

Bit late to be leaving a comment on this but nevermind. The 2009 TOBA has to be looked at both ways. It creates a monopoly, but at the same time offers some protection to retaining and apprenticing shipbuilding skills – and facilities. It runs out in 2024, so any new strategy can’t be fully implemented much before then, but some detailed planning can be done. And I agree with the last comment, the strategy does provide flexibility in case we (Scotland) leave the union. I think that for longevity in keeping shipbuilding in the UK / rUK, the design cycle… Read more »