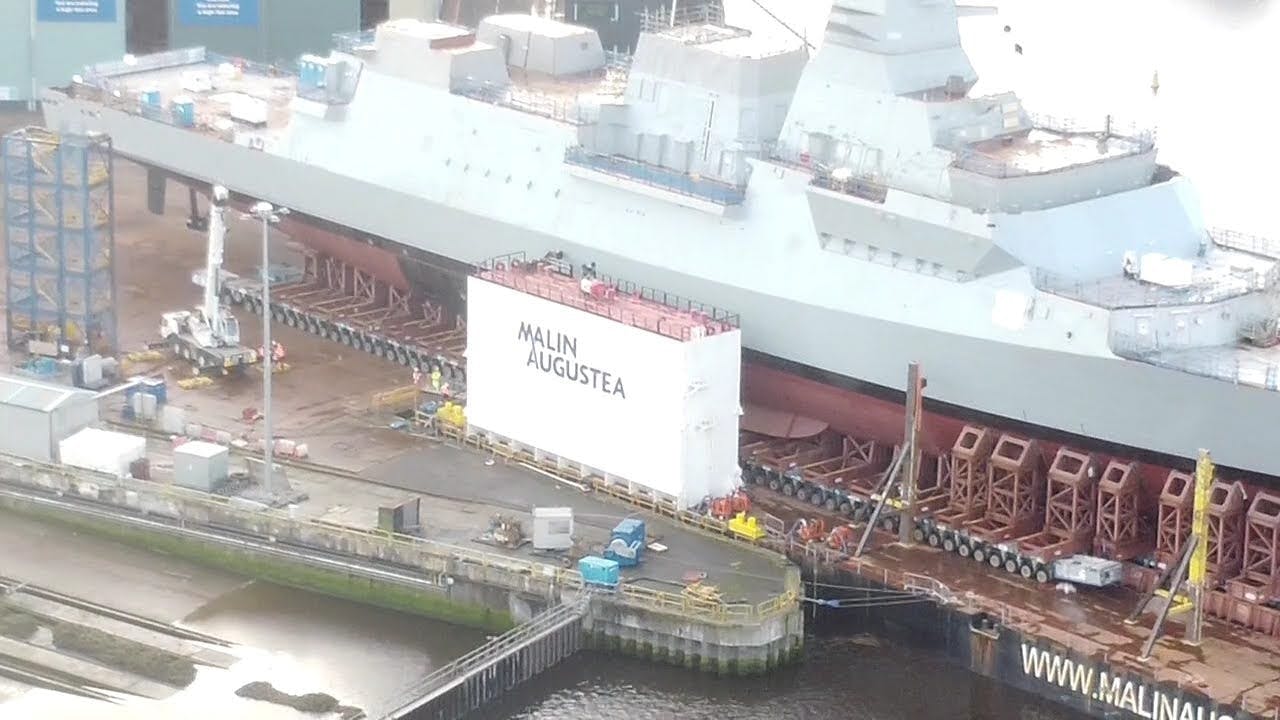

New footage shows HMS Cardiff, the second of eight Type 26 Frigates, being moved from land onto a submersible barge before being floated off downriver.

Over the coming days, the ship, currently weighing nearly 6,000 tonnes, will undergo a series of complex manoeuvres to move from BAE Systems’ Govan shipyard by barge, be towed downriver to a deep-water location in the West of Scotland, and be lowered into the water.

The frigate will then be brought back upriver to Scotstoun to continue fitting out. Not quite a conventional launch, but a launch nonetheless.

The ship will shortly undergo a series of complex manoeuvres to move from BAE Systems’ Govan shipyard by barge, be towed downriver to a deep-water location in the West of Scotland, and be lowered into the water. pic.twitter.com/LuBvU8XjLw

— UK Defence Journal (@UKDefJournal) August 21, 2024

Once in position, the float-off will involve slowly submerging the base of the barge over several hours until HMS Cardiff fully enters the water. She will then return to BAE Systems’ Scotstoun shipyard further along the Clyde, where she will undergo the next outfit stages before test and commissioning.

Here’s a gallery of images.

[su_custom_gallery source=”media: 52243,52260,52259,52258,52257,52256,52255,52254,52253,52252,52251,52250,52249,52248,52247,52246,52245,52244″ limit=”30″ link=”image” target=”blank” width=”200″ height=”120″ title=”never”]

For those wondering how they moved the ship, little wheeled vehicles were moved under the vessel, you an see this on the previous frigate, HMS Glasgow, when she was moved in a similar way back in 2022.

According to Malin Group, the barge will initially be used to transport and ‘launch’ the Type 26 Frigates being built by BAE Systems for the Royal Navy and then berthed on the Clyde and made available to industry as required, “catalysing further opportunities for the wider supply chain in fields including shipbuilding, civil construction and renewable energy”.

John MacSween, Managing Director of the Malin Group, said previously about the barge:

“Securing this piece of equipment marks another positive step forward in the reawakening of the shipping and large-scale marine manufacturing industry in Scotland. This versatile asset, based on the West Coast of Scotland, can be used for launching and bringing ships ashore, docking vessels locally or at remote locations as well as being used to relocate large structures around the UK and further afield.

We are delighted to continue our long-standing relationship with the internationally renowned tug and barge owner specialists Augustea, as well as work with Hat-San who are bringing years of shipbuilding experience to the conversion. We are also extremely grateful for the support we have had from Scottish Enterprise in making this project a reality.”

The barge is a joint venture between the Malin Abram and Augustea and, now modified, represents one of the largest in Europe – it can submerge to load vessels and cargo with draughts of up to 12m and over 137m in length.

It will be based on the Clyde between projects.

So Soon ? ðŸ˜ï»¿

Sorry, it’s great to see this latest milestone, I’m rather hoping she is more fitted out than Glasgow, any one know ?

No. Fitting out will be done at Scotstoun, just like Glasgow. The process ought to be somewhat faster, though.

Thanks, I’m no expert and I’ve never served, just thought she might have been a little more complete than Glasgow was.

A reasonable expectation.

What I really love about this video is the contrast between the Old and the New. Here is a Modern Frigate being gently moved onto a barge so she can be moved down the river and floated off.

To the left of the Barge is the old Slipway that was used for the Assembly and launch of the last 5 T45. It’s a hell of a contrast but it’s just so surprising how intact the old is, the drag chains are still piled up, just like some ship has just left the yard.

A bit of History.

Both the T45 and T26 are block builds but the blocks were assembled completely differently due to the available tech.

The T26 has been assembled in 2 halves and joined on the hardstanding outside the Block Assembly Halls and when finished rolled out via the RO/RO quay that was built for the T45

The T45 by contrast was built from 6 major hull blocks and some of those were built elsewhere and barged up to Govan. They were then rolled onto the hardstanding and moved into the gap you can see in the slipway. They were then jacked up a skid either up or down the slipway and the 2 halves Assembled in a set order.

Once they were ready a removable section of the Slipway (which is behind the head of the Slipway in the images) was put in place.

They then slid the upper half (Bow section) very carefully down to meet the Stern Section so it could be welded up.

And then it all got launched with a few hundred tonnes of drag chains to stop it hitting the opposite river bank.

It may seem a weird way of doing things but in 5 years they delivered 6 ships, and 5 were all done this way.

And it’s all just sat there 🤔

Nicely written ABC as you make it all sound almost romantic. It is a creation and birthing process of sorts. Nothing quite a new ship taking shape. Looks great. Lol. 😆

Do they even need that old slipway anymore?

I asked or mentioned that a few years back and was told that it was not useable due to the size of the newer ships and the need to retard their momentum before they ran aground on the opposite bank !

It does seem a little strange when you take an Aerial look that the whole area has been left alone in favour of the new hall.

Then again, I’m no expert.

I’m told it was because it’s a strain on the hull and an avoidable risk. HMS Daring was launched down a slip at Scotstoun with far more chains than the Govan 5. It’s way narrower there than at Govan and they launched far larger ships at Fairfield than they do these days HMS Renown, Anson, Implacable to name a few.

As for using it for extra capacity, I really can’t see the need or any sense in doing so. Assembly outside is slow, subject to the weather and weld QC must be a bloody nightmare. Far better to add shifts in the New Hall and speed the process up, just like BAe says they can.

BAe are seen as the big bad wolf because they have shut numerous sites and merged businesses, none likes to see it happen but ! The fact is post Cold War it was necessary to consolidate to keep any capacity as the market had shrunk or in the case of AFV completely vanished.

The only thing stopping BAe from really maximising their new facilities and capacity to boost the build rate is the lack of new orders.

They would be mad to speed up without either of those as they just run out of work quicker and then they will shut. So either an export order or more T26 for the RN is needed.

Is it possible that the T45 have steel covered with paint on the hull compared to T26 which has part of the hull covered with sound deafening material which is much more likely to be damaged the reason for the change in launch process.

I’d say better to keep the option of building a 3rd vessel the traditional slipway way in case we find ourselves in urgent need of more ships. But who knows what is planned.

Ha ha, “in case we find ourselves in urgent need of more ships” Don’t be silly, we haven’t enough crew or facilities for that !

Ever decreasing circles.ðŸ˜ï»¿

Maybe BAE will set the apprentices to work there on another T45 😂

To be perfectly honest now they have ironed out the bugs, I’d love to see a B2 T45 ratter than a larger T83. It’s a decent size, we still haven’t reached its maximum growth potential and it’s available now.

Personally I’d shrink the Hanger for a single Wildcat and fit extra CAMMS there, put a 5†gun up front, 48 Astors and whatever you fit in 2 MK41VLS.

It may be smaller than a Chinese Type 55 but so what, its numbers we need !

It’s tempting. What I don’t understand is the extent to which ‘future air dominance’ depends on a bigger hull ( than T45).

There does seem to be an attitude that if you have more missiles you have a more powerful ship. That’s only true if all else is equal or you don’t get taken out before you get to use those extra missiles. In other words it’s more nuanced though one thing that is consistent is that more missiles you have the less need to re supply them so obviously it’s a bonus.

I would accept that argument. Adding the Ceptors to T45 is clearly necessary even for non state actors, as evidenced by Diamonds Red Sea experience. But I suspect there’s a point of diminishing returns. Where that is, I don’t know.

My query was to do with how much of the effectiveness and scaling of FAD might depend on architecture, on say a large central platform versus software, radars and distribution of resources. All a long way off I suppose. Some other thoughts; is it meaningful to think in terms of iterative development of FAD; e.g. a couple of batch 2 Type 45s? Definitely useful. Just throwing ideas out.

I would prefer 2 x 5″ guns in sponsons, one on either side of the ship, instead of on the bow, Move the entire bridge forward into the old gun placement and give the extra room gained to anti ship missiles and more vertical launch tubes.

Given T26 is now £840 per ship with potential to reduce further with new hall etc. I would either build an extended version, or do something with the mission bay for more VLS etc.

Dimensionally it is very close to T45 size, but should be better. Clearly a better radar set up is needed, perhaps using the paired set up of T45 with more modern lighter products.

Would really like to see us standardise on CTA40 and also some form of stanflex, bringing the adaptable strike frigate flexibility to both T31 and T26/83

Weight and height required for radar are possibly the main drivers of hull size. If you want more missiles take along an extra hull or two.

T45 could remain on station and T31 role up fire off missiles and swap out with another T31 making best use of the expensive radar and large hull required to support it on the T45.

Or even the arsenal ships which are sometimes talked about. T33?

Land based systems often have multiple launch vehicles in order to get the number of missiles required.

I guess there’s no finaincial incentive to remove the chains?

They would disappear inside 48 hours round here, had my garden table nicked once, anything metal is not safe.

Is it me or does she look more complete than Glasgow did at the same stage ?

I asked the same, still waiting to find out but she does look further on all the same.

Probably totally irrelevant but sections of the new launch tower at Boca Chica are decidedly more fitted out than those for the first one, having learned from that first construction. So perhaps a similar learning curved just may have been implemented here, but as I say this is Britain.

Seems logical doesn’t it.

When does the bottle of Champagne/Scotch thing happen?

Daffodils welcome, ‘leaks’ are not! 😉

[btw, is Cardiff heading down the Clyde today? I would have like to have taken my grandsons down to the riverside to see her going by but couldn’t find any info advising when this would happen]

highest tide this week is predicted as 4am this Friday. I was talking to someone within BAE Scotstoun this week & got the inkling that it could be an overnight move.

Thanks. If early morning (even the grandsons are not up that early), looks like we might have to wait for the next one.

I wonder if more fitting out will be done in the new assembly shed for hulls 3 and beyond.

Not the main mast or sails, the roof is to low.

“120 wheels on my wagon, & I’m just rolling along…”

Great to see progress on our T26s.

ha, At least we have progressed from the “One Wheel” in the original song !

Can you imagine the fun you could have with a young Apprentice. Go outside and check the Tread and PSI on the Tyres. 🤣

Long weights, Stripey paint, left handed spanner, Hammer 4 ! ha ha, yes it’s no fum being an apprentice. 😂

You joke but they’re safety critical items, so legit someone will have to check.

And because I need a life, it’s “1024 tires on my wagonâ€

Yes, it’s good to see T26 build progress. Looking forward to hearing how the fitting out of Glasgow is going. It looks as though it’s been decided not to lifex Northumberland. The tracker shows her in Plymouth. No pressure then….!