On the south bank of the Clyde, in a part of Govan that has changed as much as the industries that once defined it, stands a building most Glaswegians have never seen inside. To one side, police helicopters rise from the city’s main helipad, and on the other, one of Europe’s largest hospitals.

Across the river, new glass-fronted developments look toward the shipyards where Royal Navy frigates take shape. Between them, in a quiet industrial facility that still hums with the rhythm of engineering, Thales Optronics and Missile Electronics goes quietly about its work.

From the outside, it looks unremarkable. Inside, the atmosphere feels closer to a laboratory than a factory. Engineers sit under white light, adjusting optics and calibrating sensors that will soon guide the eyes of Britain’s most advanced vehicles and submarines.

Govan has changed, and so has Thales. The site’s work traces a direct line back to Barr and Stroud, the Glasgow firm that built the Royal Navy’s first periscopes. The name is different and the technology unrecognisable, but the same precision, craft and quiet pride still shape what happens here.

For more than a century this site has been shaping how the nation sees its enemies. The company’s lineage runs back to 1888 when two Glasgow University engineers, Archibald Barr and William Stroud, began producing optical rangefinders in a tenement workshop off Ashton Lane. Their firm, Barr and Stroud, went on to supply the Royal Navy with the periscopes that equipped every submarine through two world wars. The name above the door has changed, but the spirit of precision and innovation remains.

A line that runs from Barr and Stroud to the present day

The visit began with a short briefing from Martin Parker, a former RAF fast-jet navigator whose career has taken him from Tornado squadrons to Eurofighter simulators and now to a facility that produces optical systems for land, sea and air. We soon headed out to the facility for a tour.

“This is the original advert from Engineering Magazine of May 1888,†Parker said proudly when we were in the atrium area of the facility, “a note from the War Office requesting tenders for range finders for infantry. Paragraph three says a person of ordinary intelligence and normal vision must be able to become an efficient range taker after a month’s training.â€

“Doctors Barr and Stroud got together in Dr Barr’s bedroom and came up with a design for a range finder. This is the second one they ever made,†he added. “The Army loved it because it was dead easy to use and because of the quality of the optics. Up until then, all of the binoculars and periscopes had been imported from Germany.â€

When the Royal Navy learned of the design, Parker said, “they said, ‘That’s okay for the Army, but we’ve got warships.’ Those ‘drain pipes’ on the front of First World War battleships were actually Barr and Stroud range finders.â€

He reflected on how the site itself has evolved over time. In the post-war years, the old industrial model had become unsustainable, much like the wider shipbuilding sector along this stretch of the Clyde. The present facility occupies what was once the Alexander Stephen shipyard. Pilkington invested in redeveloping the site and relocated operations there in 1992, beginning work on the non-hull-penetrating mast for submarines that would become a key innovation in British naval design.

Parker spoke about how deeply these origins are tied to Glasgow’s identity. The name Barr and Stroud still resonates across the city as part of its industrial heritage. The company’s original premises in Anniesland have since been converted into shops, pubs and cafés, but the technical lineage endures. The expertise that once defined Glasgow’s West End now continues a few miles downriver in Govan, where the same tradition of optical precision remains central to the Royal Navy’s submarines. Every boat ever built for the service has carried a periscope made in Glasgow, a continuity stretching back to 1888.

As he spoke, he made clear that continuity matters to the workforce. The names have changed, Barr and Stroud, Thomson-CSF, now Thales, but the purpose has not.

Inside the restricted zones of the plant, the soundscape is subdued: a steady hum of extraction fans, the click of switches, the occasional whir of a testing rig. Each product is hand-built and tested in its own chamber, more akin to a physics lab than a factory floor. Engineers calibrate stabilisation systems, align lasers and check thermal cameras against controlled heat sources.

The site’s output spans the armed forces. For the Royal Navy, it builds the periscope and optronic mast systems that equip Astute-class submarines. For the British Army, it produces the stabilised camera and sighting systems installed on Ajax reconnaissance vehicles and Challenger 3 tanks. And for the Royal Air Force, it supplies elements of the Elix-IR threat warning system soon to be fitted to the E-7 Wedgetail and A400M Atlas aircraft.

Digital Crew and the shift to data

One of the newest developments on show was the “Digital Crew†project, a concept that turns years of optical expertise into a data-driven command system. In a demonstration suite, a series of screens displayed a simulated battlefield seen through multiple sensors: visible light, infrared, short-wave infrared and acoustic. Within seconds, the system had fused the data into a single panoramic image, tagging potential threats automatically.

“It sits metaphorically next to the crew,†Parker explained. “It learns from what it sees. If something moves differently or doesn’t belong, it flags it before a human could.†The idea is not to replace human judgment but to give soldiers and sailors an extra pair of eyes. The aim is to create a system that can migrate seamlessly across domains.

Digital Crew represents a shift in identity for Thales Glasgow. Once known solely for optics, the site is now a software and systems-integration centre, connecting sensors, lasers and cameras into a unified digital picture. Turning pixels into decisions.

More on this soon as part of our series on what goes on inside Thales UK in Govan. Stay tuned throughout the week for more.

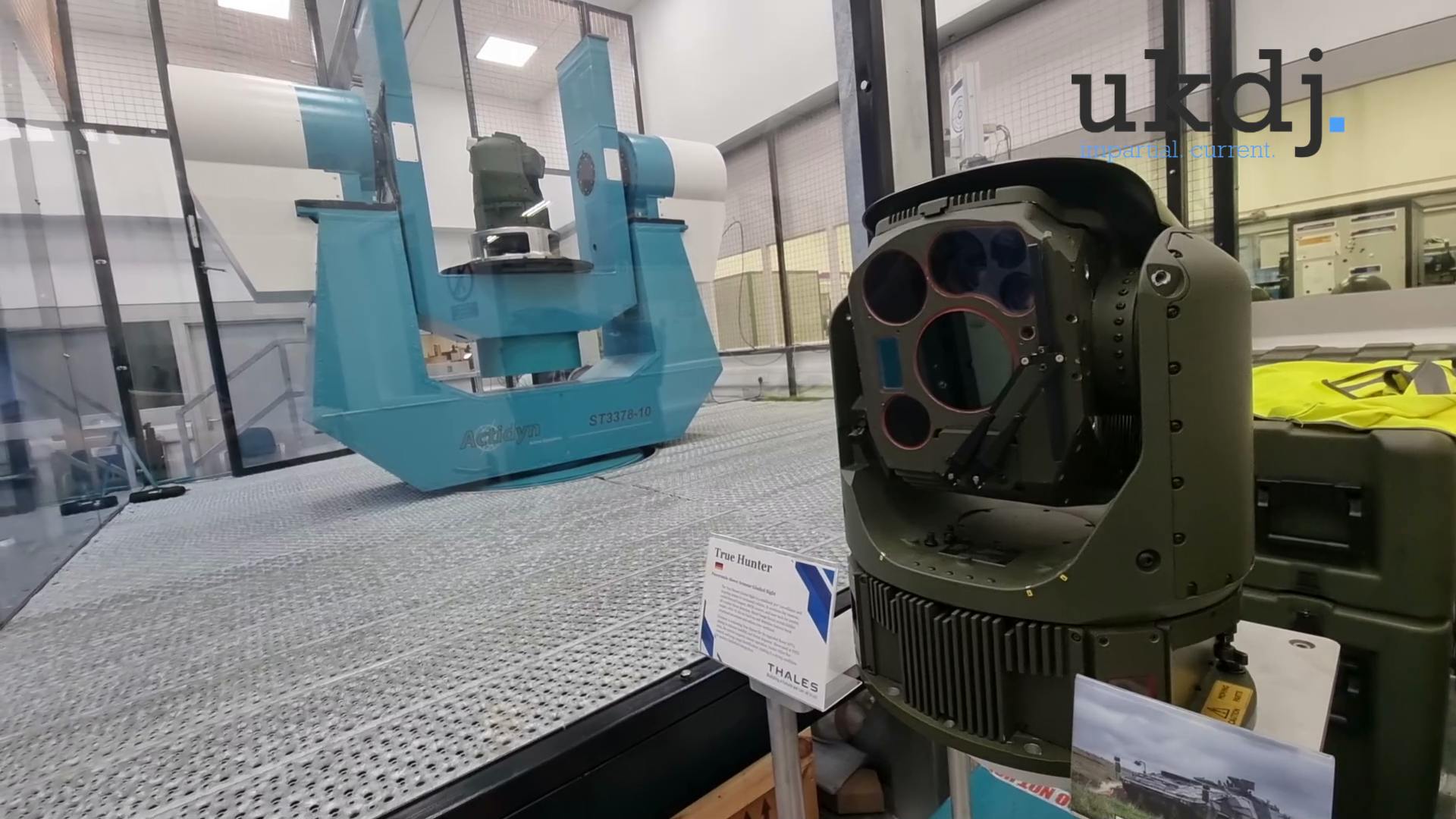

TrueHunter

Few products illustrate the site’s expertise more clearly than the True Hunter family of stabilised sights. These compact optical turrets, developed and built in Govan, are fitted to the Challenger 3 main battle tank and Ajax reconnaissance vehicle and have been selected for the German Army’s Boxer programme.

The device itself resembles a small turret about the size of a helmet, matte grey and solid. When activated, it locks its field of view with remarkable precision, compensating instantly for movement. “Three screws and two connectors,†Parker said with a grin. “You can remove and replace the entire unit in five minutes.”

Engineers on the shop floor refer to the system as a benchmark in its class. One said quietly, “There is nobody on the planet who can match what we do here. The stabilisation precision, the image clarity, the modular design, it’s world-leading.â€

More on this soon as part of our series on what goes on inside Thales UK in Govan. Stay tuned throughout the week for more.

From periscopes to electronic masts

Upstairs, the tour reached the ‘tower’, where technicians were working on the CM10 optronic mast, the successor to the conventional periscope. The mast allows submarines to see 360 degrees around the vessel without cutting a large hole through the pressure hull, transmitting high-definition imagery and radar data down an electronic link.

This technology is now being taken a step further for the Royal Navy’s Dreadnought-class ballistic missile submarines. In 2023, Thales was awarded a £169 million contract to provide a new Integrated Combat System Mast, the most advanced in the world. Each submarine will carry two of them, each combining visual sensors, electronic warfare tools and communications systems within a single housing.

The design builds on a century of development that began when Barr and Stroud delivered the Royal Navy’s first submarine periscope. Every British submarine since has carried a Glasgow-built optical system. The Dreadnought mast is smaller, quieter and more capable than any of its predecessors, incorporating a next-generation radar electronic support system. The site’s engineers are clear that Glasgow is the only place in the world able to manufacture visual systems at this level of precision. “At this level, there is nobody else,†one told me. “Particularly with stabilisation and the integration of optical and electronic systems. It’s irreplaceable capability.â€

More on this soon as part of our series on what goes on inside Thales UK in Govan. Stay tuned throughout the week for more.

Miniaturisation and cross-domain innovation

A recurring theme across the visit was miniaturisation. Parker lifted a small cube of equipment, roughly the size of a shoebox. “This is Sasha,†he said, referring to the compact sensor array. “Eight cameras in visible, infrared and short-wave bands, all perfectly aligned.â€

That kind of compactness has transformed both land and naval systems. Reducing size and power requirements has allowed engineers to fit more sensors into smaller masts, giving submarines and armoured vehicles greater awareness without adding weight or noise. The same miniaturisation work has fed into Thales’s new Integrated Combat System Mast for Dreadnought, making it one-third the size of earlier models.

The company calls it cross-domain innovation: lessons learned on land improving performance at sea and vice versa.

People behind the precision

In the design centre at Govan, I met some of the people who keep Britain’s most sensitive optical systems working. Martin Parker introduced them one by one: engineers from both land and maritime teams, several graduate apprentices, and veterans of the armed forces who now apply their experience in industry.

One engineer, responsible for maintaining the Warrior sighting system, described how his work keeps the vehicles operational until the new Ajax fleet is fully introduced. Another, a former submariner, spoke about the importance of reliability beneath the surface and how his team supports the fleet when an optronics mast or periscope needs urgent attention. If one mast fails, a boat can stay on patrol; if both fail, it must surface and return to port. Their job, he said, is to make sure crews can remain safe at sea.

Ellen, a graduate apprentice, discussed her move from thermal imaging cameras to the design of vehicle sighting systems. She reflected on learning how to balance performance with manufacturability and field durability, paying close attention to details such as cable routing and accessibility. Her comments captured a theme that ran throughout the visit: an emphasis on safety, usability and endurance.

The discussion soon turned to how the design teams learn from those who use their systems. Parker mentioned a recent visit by Royal Engineers from Leuchars who, rather than posing for photos inside a vehicle, immediately inspected its underside to understand maintenance access. That, he explained, was the kind of feedback that shapes design decisions and informs judgments about acceptable levels of wear and degradation.

A senior engineer outlined the twin priorities facing the site: sustaining the operational availability of current platforms while ensuring that future programmes such as Dreadnought deliver new levels of capability. He spoke of the company’s gradual shift from supplying individual components to delivering complete, integrated systems, a transition he viewed as transformative for the business. Reflecting on Glasgow’s role in defence innovation, he said the site remains the only place in the United Kingdom capable of producing visual systems at this level of sophistication.

Then he put it bluntly but fairly: “This site is the only place in the UK that has the capability to provide that visual system, actually the only place in the world at this level. Nobody on planet Earth can match what we do.â€

That sense of purpose runs deep. Around fifteen percent of the workforce are veterans, many bringing first-hand operational knowledge into the design process. Twice a year, the company hosts “Military Inside Days†for personnel approaching the end of their service, encouraging them to consider second careers in engineering. Parker explained that employing former operators helps the company learn earlier and design better for those still serving.

He recalled one example of collaboration with submariners that led to a subtle but important ergonomic improvement to the Astute-class control station, an adjustment that made it easier for operators to maintain control without breaking concentration. Such refinements, he said, arise only when end users are directly involved.

Inside the labs, this approach has become routine. Engineers now run workshops with service personnel to test the layout of controls, button placement and the logic of user interfaces. Operators are invited to sit at the console, handle the controls, and identify what feels intuitive. The smallest design choices, such as avoiding a button where a notepad might strike it or a key where someone’s hand naturally rests, can matter under pressure.

Younger service members, engineers observed, bring different expectations shaped by civilian technology. Many prefer control interfaces that resemble familiar gaming devices, asking for Xbox or PlayStation-style inputs. The teams in Govan design accordingly.

Inspiring the next generation

Away from the workshops and test rigs, the team at Govan is working to get more young people interested in engineering. Thales partners with the charity SmartSTEMs to help pupils across Glasgow understand what a career in science and technology can offer. The company runs visits, mentoring sessions and events where engineers show how the skills learned in school can lead to real jobs in industry.

It also works with six partner schools in the city. It was explained to me that those schools were chosen because they are in areas that have not always benefited from the same access to employers or industry links. The aim is to make engineering feel like a realistic and rewarding option for every young person, not just those who already have a clear route into it.

Parker put it plainly: “We’re proud not just of what we deliver for the armed forces, but of what we bring to the community, from local schools to the charities we support across the city.â€

A Glasgow story

Thales’ leadership recognises that its presence in Glasgow can attract scrutiny. Defence work divides opinion, yet the company regards its role as both industrial and civic. The importance of public understanding was not lost on me, the systems produced here on the Clyde are designed to protect lives and are built responsibly.

Inside the facility, the atmosphere is one of careful, methodical work. Engineers develop stabilised optics, thermal cameras and sensor systems that improve visibility and control for crews in complex environments. The products that leave Govan are meant to enhance perception and safety for those protecting us.

That distinction has become clearer during the war in Ukraine. Systems built in Glasgow have contributed to early-warning networks that detect aircraft and drones, providing civilians with precious seconds to seek shelter. Some rely on technology first developed decades ago, yet they continue to save lives, demonstrating the enduring value of the work done on the Clyde.

Opening such a site to journalists is uncommon, but the decision signals confidence in both the workforce and the city. Glasgow’s role in the United Kingdom’s defence industry is seldom part of national industrial debates, though its contribution is substantial. As I stepped back outside, the sound of testing rigs faded into the traffic along Govan Road. It was a reminder that this unassuming building houses a continuation of the industrial spirit that once defined the Clyde.

(1995-1999) I could bore you with details (MIL-STD-498, RTSASD, Ada, PID control-loops) of how our software team contributed to the success of CM10 Optronics Mast.

I don’t think most of us would be bored provided it didn’t breach confidentiality and OSA.

Must have been a very interesting project at the time when not everything was digital first.

It was an interesting watershed project for Thales UK, with a team of Brit and French professionals ENGINEERING software.

An excellent article George, about an excellent part of our defence industry.

These longer-format articles allow you to get so much more information across.

Yes, an excellent in depth article, thanks for taking the time and trouble bringing this to your brilliant site.

I personally had no clue what they did there.

I have visited this facility in a professional capacity and it certainly is like entering a spacecraft. Great place, great work, great products.

French not British.

I recall an interesting Brit/Franco cultural combo!

Vive le difference?

French Owned and based in Scotland. There are numerous other Thales sites dotted around the UK, all doing valuable work and giving employment to British and many other nationalities.

How do you like the QE design ?

‘1818’ not bad for a Company that didn’t exist for the next 60+ years. Now that’s what I call truly focused vision.

… mind you imagine the number of committees they must have had to take that long to fulfil the original request.

It sounds like a lot of other defence manufacturing companies could learn a thing or two from how well Thales works with the “end-user”.

Shame you didn’t mention that this organisation is more than 50% owned by the French government and Dassault, a French company.

I think it matters.

why should it matter? it’s still britain’s most advanced military optics facility, be it owned by the French or not

Exactly.

It is physically in the UK and the IP is sovereign.

It also fully supports NATO.

I think it is called collaboration?

However, someone has to explain to Dassault what that means. As in their dictionary collaboration means, ‘Dassault leads and you do as you are told and are grateful for the crumbs’?

Is the IP still sovereign to the UK if the company is majority owned by France then? If so, how does that work legally ? (Genuine question as I have no idea).

Yes, the MoD have a large say in what can be shared or not. If the MoD believe it has an intrinsic sovereign capability. They will insist on how the item can be shared or used for export. They have the power to stop it being sold abroad, an example being the Meteor missile being sold to India for use on the Su30s.

Interesting you should feel that way.

So, how about every other Non British Company that exists on UK soil ?

Exactly my point. A sovereign British company now isn’t. Same as Rolls Royce cars….not a single British car company left (apart from little ones selling a few dozen a year.). Not a single aircraft company making planes in any numbers, all gone down the drain or bought up by foreign companies and governments. I blame it on Thatcher who destroyed our industrial base. I could go on…..