Walking through Leonardo UK’s radar and advanced targeting site in Edinburgh, it’s hard not to be struck by the sense of purpose that fills the air.

Tucked on the edge of Scotland’s capital, this facility has quietly transformed into one of the UK’s most important defence hubs, shaping the future of air combat and surveillance. I was given access to see what goes on behind the scenes.

The site itself is impressive. Over 2,500 people work here, and despite being at near capacity, the team continues to grow.

Mark Stead, Senior Vice-President for Radar and Advanced Targeting Systems, leads the site with a clear vision. “We’re in rude health as an enterprise,” he said, pointing to the site’s significant financial growth over the past five years. The increased demand for cutting-edge radar, laser, and targeting technologies has fuelled both headcount and investment. Leonardo’s Edinburgh site has become Scotland’s single largest private investor in research and development, pouring tens of millions annually into pioneering defence projects. Iain Scott, Vice-President of Capability and Chief Technology Officer, Radar and Advanced Targeting, reinforced the point: “We are financially the biggest R&D spender in Scotland.”

The facility’s strategic importance to the UK defence sector is undeniable, with continuous innovation and practical application driving its success. Reflecting on his role and the excitement of working on cutting-edge projects, Stead shared his enthusiasm:

“Well, I’m an engineer, so I can’t help but be excited by the range of capabilities that we develop and produce here. I love the fact that we’ve got that continuing heady mix within the portfolio of development and production and support, of course, support to existing capability that we have here, but also those future capabilities that we’re absolutely at the forefront of here, examples of which being GCAP, the Global Combat Air Program, which I remember as a kid that I was inspired by Typhoon at the time, which was the next generation at the time, in terms of combat aircraft platforms, GCAP is exactly that for our next generations.”

His passion for technology extends beyond the present to the future of defence innovation. Stead is particularly proud of Leonardo’s involvement in projects like GCAP and DragonFire:

“But also things like Dragon Fire, which is a really cutting-edge developmental laser directed energy weapon system where we produce the main, what’s called the main beam director for it. It’s a very exciting time for that program. But also our general product portfolio is very high-end engineering, extremely capable bang for buck, the best in the world. I’m really proud of that. I think all the people who work here are absolutely, very proud of that. And most importantly of all, what that delivers is the end user.”

Stead’s passion for engineering is rooted in his own formative experiences. He shared a personal anecdote from his school days that illustrated how early inspiration shaped his career path:

“I remember the reason I was talking yesterday about when I was 11, I won the book, the school prize for my first year at secondary school. And I got to choose any book that I wanted up to a value of, like, 15 pounds or something. The book that I chose, I’ve still got it at home, is Modern Combat Aircraft. I’ve still got it on my shelf at home. And on the first page is the Saab… Actually, it’s not the Gripen, nor before that… it was the Draken.”

This childhood fascination with aviation technology set him on a path toward his current role. Stead fondly recalled:

“I remember showing it to my… because we obviously work a lot with Saab… showing it to my Saab customer because it’s got my school prize sticker emblazoned in it over the Viggen aircraft. And of course, we’ve supplied the radar into Gripen now as well.”

Beyond Edinburgh

Leonardo’s Edinburgh site plays a critical role in the UK’s defence ecosystem, not only for the advanced systems it produces, but also for the degree of sovereignty it helps maintain. While Leonardo is an international company headquartered in Italy, its UK operations have a distinctive structure that supports national control over sensitive technologies.

“Leonardo UK is its own legal entity, and there are lots of reasons why that should be the case,” said Dave Shaw, Vice President of Sales. “We design, develop and deliver leading UK capabilities. So being UK-specific is important to us.”

Although the internal structure spans several business lines, the company encourages a unified public identity simply as Leonardo — reflecting the collaborative strengths of being part of a wider international group while delivering sovereign capability from within the UK. This balance allows the UK to retain assured access to high-end technologies and avoid potential export restrictions or foreign dependencies when equipping its armed forces.

Despite its rapid growth, the Edinburgh site has had to adapt to some practical challenges. To accommodate the increasing demand, Leonardo opened a second engineering centre in Newcastle, creating nearly 100 new jobs in just two years. “Newcastle was opened because we fished the Central Belt pretty dry,” Scott explained.

This strategic move reflects the company’s adaptive approach to growth. Rather than allowing manageable limitations to hinder progress, Leonardo found a way to maintain its momentum while fostering new opportunities elsewhere.

Export plays a crucial role in the site’s output, with around 50% of products, including radar systems, lasers, and defensive countermeasures, going overseas. The site’s technology is already in service with the US Coast Guard, Brazilian Air Force, Swedish Air Force, and other NATO allies.

“About £100 million a year goes into the Scottish supply chain,” Stead noted, highlighting the broader economic benefits for the region. This global reach underscores Edinburgh’s role as a critical player in international defence, with systems like Osprey and Miysis gaining recognition worldwide.

Behind the scenes with Leonardo’s ECRS Mk2 Radar

One of the most significant projects is the European Common Radar System (ECRS) Mk2, set to be integrated into the RAF’s Typhoon fleet. The ECRS Mk2 represents a revolutionary leap from the older Captor-M system. As Iain Scott described it:

“Captor-M was probably the high-water mark in terms of mechanical scanned radar systems in the world. But ECRS Mk2 takes it to a whole new level. It’s about bringing multifunctionality to a radar platform that can do more than just track targets.”

The Mk2’s Active Electronically Scanned Array (AESA) technology enables multi-mission capabilities, combining traditional radar functions with advanced electronic warfare. This integration means that the radar can perform air-to-air surveillance, ground mapping, and electronic attack simultaneously.

“The ECRS Mk2 is what we would call a multifunction system. It’s doing radar and EW,” Scott explained. “It’s got a big aperture at the front. It’s very, very wideband — it will be the most wideband in terms of RF frequencies that will operate over in the world, much wider than any US system.”

This broad frequency range allows the radar to detect and disrupt enemy systems without revealing its own location, a crucial advantage in modern air combat, you can read more about this system in the feature below.

The business of survival – Up close with Miysis DIRCM

Another standout development at Leonardo Edinburgh is the Miysis Directed Infrared Countermeasure (DIRCM) system. This system uses directed laser energy to disrupt infrared-guided missiles, providing an advanced level of protection compared to traditional flare-based countermeasures.

Dave Shaw explained the significance:

“Historically against IR threats, it has been flares, but flares are limited in terms of their numbers. They’re not as effective against modern multi-spectral missiles.”

Miysis, by contrast, offers continuous protection without the risk of running out of countermeasures. This makes it particularly valuable for long-duration missions, where the risk of repeated missile attacks is high. The system’s compact design and low power consumption make it suitable for a wide range of aircraft.

During my visit, I had the opportunity to watch footage of Miysis in action during a demonstration. Just seconds after launch, the system detected the incoming threat, firing its laser and causing the missile to veer off course. Shaw pointed to the screen: “When you see it start to spin, that’s the seeker head on the missile not really knowing where it’s going.”

Miysis has already been integrated into various military platforms, including rotary and fixed-wing aircraft. Its success has positioned Leonardo as a leader in DIRCM technology, setting a new standard for active infrared countermeasures.

You can read more on what I learned about Misys by clicking the feature below.

It’s not all fighter radars and lasers

Leonardo’s Osprey radar stands out for its unique fixed-panel design, which removes the need for moving parts typically associated with traditional gimballed surveillance radars. This allows the system to be installed in various aircraft without compromising performance or structural integrity.

The design enables full 360-degree situational awareness while keeping the aircraft’s underside clear—an important feature for platforms such as search and rescue helicopters that need to land in snow or at sea.

Beyond its defence applications, Osprey is also proving its value in civilian operations. The system has been adopted by Norway for use on its new fleet of search and rescue helicopters, where radar performance can mean the difference between life and death. “They talk about finding targets in the water — people who’ve gone overboard — in single-digit minutes, rather than an hour and a half or never,” said Stead.

In turbulent sea conditions, the radar’s ability to distinguish between waves and small objects gives crews a critical edge during rescue missions. You can read my item on Osprey below.

How do they test the radars?

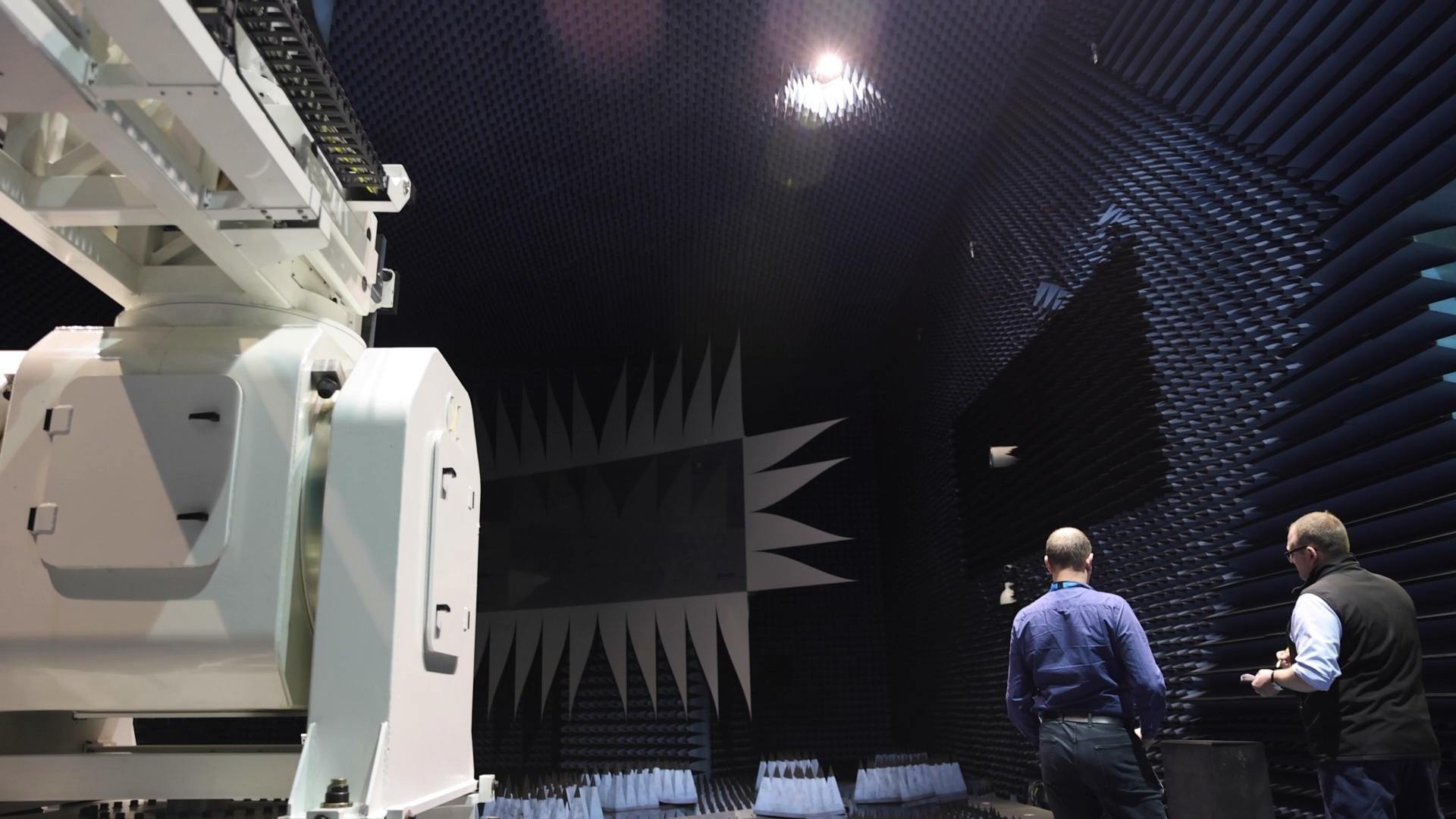

One of the most fascinating aspects of radar development at Leonardo’s Edinburgh facility is the testing process, particularly the use of the Compact Antenna Test Range (CATR). This state-of-the-art facility is essential for evaluating the performance of advanced radar systems before they are deployed on aircraft. During my visit, Craig, an engineer at Leonardo, walked me through the intricacies of the CATR and explained why it’s a crucial part of radar development. The room itself is sizeable — about 30 metres long and up to 20 metres wide — and lined with radar-absorbing material to prevent external interference. It’s one of the largest CATR facilities in Europe and offers a high-security, noise-free environment where engineers can accurately test radar performance without any signal contamination from the outside world.

The key to the CATR’s effectiveness is the seven-axis positioner, a sophisticated piece of equipment that moves radar systems in multiple directions to simulate how they would function in dynamic scenarios. At the top of this positioner, the radar or antenna system under test is mounted. It can accommodate anything from an individual antenna to a complete radar system. The setup includes concave mirrors that reflect the radar signals in a very specific way. The signals are transmitted from a horn antenna, bounce off the concave mirrors, and then hit the radar being tested. This arrangement allows the radar to receive signals as if they were coming from a distant source, even though the actual distance in the room is only a few meters. This technique effectively mimics the conditions of long-range detection in a compact space.

One of the key advantages of using the CATR is that it eliminates the need for outdoor testing, where weather and environmental factors can affect results. Instead, testing in this controlled environment ensures consistency and accuracy. Moreover, the facility’s shielding means that classified tests can be conducted without risk of signals leaking out, which is crucial for maintaining security.

A Sense of Responsibility

As I wrapped up my visit, it was clear that the team at Leonardo Edinburgh takes great pride in their work. The focus is not just on technological advancement but on delivering practical, reliable solutions that make a difference in real-world defence scenarios. That ethos resonates throughout the site, from the testing floors to the meeting rooms where future projects are planned. The engineers are not only committed to excellence but also to a sense of duty, knowing that their work directly impacts the safety of military personnel worldwide.

This global reach underscores Edinburgh’s role as a critical player in international defence, with systems like Osprey and Miysis gaining recognition worldwide. One of the most striking aspects of the Leonardo site is the sense of collective purpose. Engineers, technicians, and support staff work closely, often overlapping in their expertise and roles. This collaborative culture is central to the site’s success, allowing teams to rapidly prototype, test, and deploy new technologies.

Stead’s earlier words lingered with me:

“Our general product portfolio is high-end engineering — extremely capable and world-class in terms of value for money. I’m really proud of that, and I know everyone who works here is too. Most importantly, what we deliver benefits the end users — the men and women in harm’s way, completing missions around the world using our systems. They rely on us to provide the effects and capabilities they need to get the job done. That, more than anything else, is what drives our people — and certainly drives me in leading this business.”

The visit offered a glimpse into a future where cutting-edge technology and human ingenuity converge, driven by a sense of purpose and a commitment to safeguarding those who serve; I hope my items covering what I learned on site are helpful to you, the reader, in communicating what I learned. Stay tuned for the deep dives!

An excellent article, I’m looking forwards to the rest of the series!

Is there a way in which these longer-format articles could be distinguished from the run-of-the-mill news types, so that it’s easier to find them as a reference point in future?

Good shout, I’ll ask the team and see what can be done.

BTW, are you doing CNE 2025 coverage, or do you know a site that is?

I’ve noticed that there is a lot less in the news about it now than last year, when there was all of the excitement over Steller Fearless and all that.

Would have thought that with an SDR coming there’d be a lot of interesting news concepts.

Couldn’t attend this year due to scheduling but NavyLookout is there I think!

Thanks, I’ll look forwards to their report!

can you get a serious update on why venturer is not in the water?

Indeed – one of George’s better articles. Also George is trusted to go to more interesting places and chat to interesting people!

Hopefully we will see more of this more great quality material.

Totally agree this truly is one of Britains stand out technology hubs with a great history that needs to be treasured and promoted.

WOW, this is an amazing report, thank you George.

Let me just echo, really interesting, more please when you can.

Great to get a glimpse behind closed doors. I pass the Crewe Toll site from time to time, and although I had a fair handle, as a layman, of what goes on inside, it’s good to see things in a wee bit more detail.

More of this level of review, an excellent programme, George.

Thank you for this very informative article George.

I would like to add my voice the to complements George,

This is a very good article indeed, painting a picture of a well run and highly motivated team doing impressive, innovative and impactful work. Your enthusiasm for what you witnessed shines through in a way that could inspire future engineers.

Well done and thank you. More of these articles please as, part from being very interesting they also give a reassuring sense that things are actually happening.

Thank you

CR

Thank you George and thank you Leonardo.

One can instantly pick up the excellence, very reassuring and 110% supportive.

Incredibly appreciated.

Thanks George, this is a blast-from-the-past!

I began my engineering career in 1980 with Ferranti. At that time there were five divisions and 6,000 employees in Scotland. Infamously, Ferranti went bust in the early 1990s. It is good to know the radar division survived and now thrives.

I am biased, but Scotland does produce excellent engineers!