The Global Combat Air Programme (GCAP) has reached another milestone with the launch of a new consortium, bringing together defence electronics champions from the UK, Italy and Japan to deliver the advanced sensing and communications backbone of the future fighter.

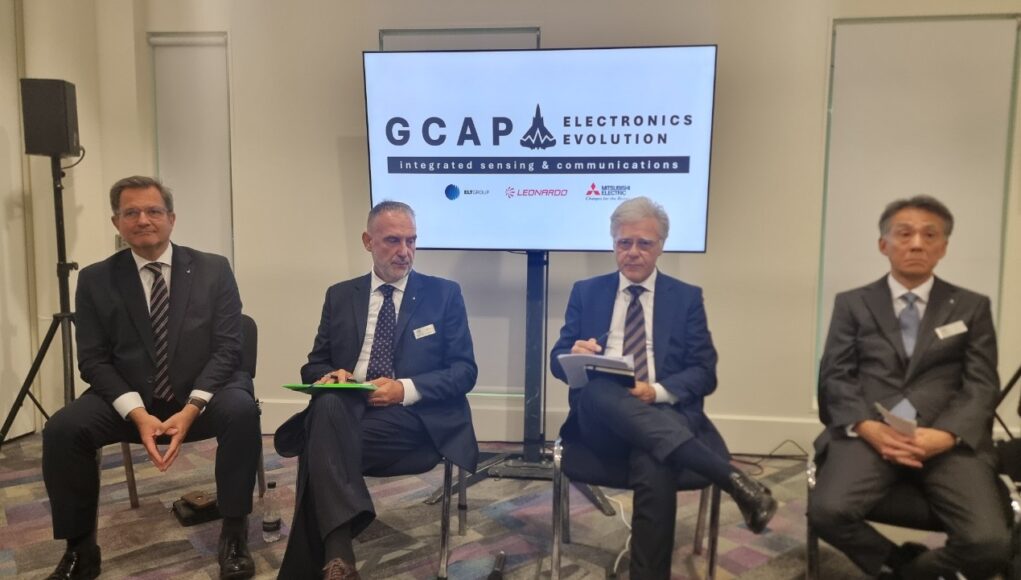

Unveiled in London on 9 September, the GCAP Electronics Evolution (G2E) consortium will see Leonardo UK, Leonardo’s Electronics Division in Italy, ELT Group and Mitsubishi Electric work together on the Integrated Sensing and Non-Kinetic Effects & Integrated Communications Systems (ISANKE & ICS).

The grouping will act in readiness to receive a contract from Edgewing, the joint venture between BAE Systems, Leonardo and Japan Aircraft Industrial Enhancement Co. Ltd.

According to the group, the formation of G2E “represents substantial progress at an industrial level and reinforces the partners’ long-term commitment to GCAP.”

At the press conference, Andrew Howard, Leonardo UK’s Director Future Combat Air, underlined the transformative nature of the work: “The essence of what it’s trying to be delivering is sixth generation. The really transformative step is sixth generation. It is a profound integration of sensing and communications to create greater capability.”

Howard explained the thinking behind the new consortium name: “What we’ve chosen is GCAP Electronics Evolution, because what we recognise is that evolution is the essence of what we’ll be delivering, a constant spiral of technical capability from software and firmware throughout the product life cycle.”

Pietro Vanotti, Senior Vice President for Future Combat Air System Programmes at Leonardo’s Electronics Division in Italy, stressed that the scale of the endeavour required multinational cooperation: “No more a single country, a single industry, can face with such a giant development. Since the beginning we understood our role was to sit down together, harmonise our capabilities, and find synergies to create something better than the sum of its parts.” He added that communications would be “the glue that make all the sensor capable to work as a single sensor, connecting different platforms across the battlespace.”

For Ing. Alberto De Arcangelis, Senior Vice President at ELT Group, “Next Generation” means more than improved performance: “Next Generation does not mean only that we are going to develop a product with next generation functions. It means being fast in the development, complying with tough timelines, and securing through-life upgradability.”

He described how the consortium would deliver this through shared engineering: “Most of the development activities will be performed by joint integrated teams. Engineers from all four companies will work shoulder-to-shoulder in co-located teams, providing the best mix of skills and ensuring freedom of action and modification for each nation.”

Tatsuya Hirao, General Manager of the F-X Programme at Mitsubishi Electric, called the venture a landmark for Japan’s defence industry: “Participating in this dynamic consortium is a milestone, not only to bring our own heritage in advanced sensing and communications, but also to learn from the remarkable experience of our partners, by literally working around the clock across continents.”

Howard noted that the collaboration was moving beyond strategy to practical engineering: “Our MELCO colleagues are arriving in the UK, joining my team in Luton. That isn’t a person coming here to strategise or talk work share, that’s a person coming here to get on with some engineering.”

The consortium has signed its agreement as a precursor to receiving the first international contract, which Howard described as “the beginning of the next chapter.”

With GCAP aiming to deliver an operational sixth-generation fighter by 2035, the partners pushed the need for both speed and resilience. As De Arcangelis put it: “Next Generation means a superior understanding of the battlespace scenario, enabled through full integration of all the sensors and communications functions, with state-of-the-art data fusion and the newest artificial intelligence and machine learning algorithms.”

The GCAP Electronics Evolution consortium now joins Edgewing and other industrial groupings in shaping one of the most ambitious multinational defence programmes underway today. For all the technical language of integration, data fusion and digital engineering, the message was clear: the future of combat air will be written not by one nation alone, but by partners willing to share knowledge, risks and ambition. In that collective effort lies the promise of a fighter designed for a battlespace yet to be defined.

They also confirmed that each nation will have a specific avionics demonstrator aircraft – the current British Excalibur 757, an Italian system based on a business jet and a Japanese aircraft built off a Kawasaki C-2 cargo jet.

Good that progress is being made.

I just hope France and Germany are kept at arm’s length.

Germany can buy them only. This ac will be a world beater….

It’ll be very good. I’m not sure about ‘world-beater’, given its been a very long time since the UK, Italy or Japan produced an aircraft that was significantly ahead of pack. World-beating subsystems, perhaps, but the final jet will probably still lag behind Chinese and American systems.

The United States has not produced a wholly American fighter in nearly three decades (F22). Even then it was hugely expensive. Boeing has not put an originally designed and operational fighter into service since 1934. The F-47 is nothing to date bar an artists drawing and X-prototypes, which may or may not be misleading. China, well there is so much misinformation the only thing you can rely on is it containing stolen intellectual property. Tempest will be a bloody good aircraft, even world beating for abit.

I’m not saying Tempest won’t be capable – in fact, I began my comment by saying that ‘It’ll be very good […] world-beating subsystems’. However, it seems a little presumptuous to assume it’ll be a world-beater given there’s little recent precedent for such comprehensive quality from the UK, Europe or Japan.

There’s a slight difference between the US, doing the vast majority of design and construction on the F-35, as well work on the B-21 and F-22, and the GCAP partners, who’ve at most contributed subsystems to the F-35. When was the last time BAE and its partners delivered a fighter aircraft that was significantly superior to the competition? The Typhoon was very good, but not comparable to the Raptor, and superseded the Rafale by little margin. Now that Typhoon is receiving things like an AESA, there are aircraft that vastly outstrip its capabilities in service or emerging globally.

It seems odd to both claim that the F-47 is little more than an ‘artist’s drawing and X-prototypes’, and then to argue that any Chinese design will include stolen IP. Where are the Chinese stealing from? Might it be that the second-largest economy in the world, with a pair of fifth-generation fighters in production and one of the most comprehensive education, engineering and technology bases globally is capable of producing its own technology?

Tempest will be very good. It’ll be competitive with fighters across the globe, both today and in the future. But claiming it to be a ‘world-beater’ a decade before the planned entry to service, before a demonstrator has flown, as the first fighter designed by the partners in forty years, seems a little hubristic and presumptuous.

Companies build aircraft, not countries. The B-21 you cite is built by Northrop Grumman, a competitor to Boeing.

Boeing hasn’t built a single stealth fighter, it’s one attempt, the X-32 prototype losing to the Lockheed Martin X-35 in the competition for the JSF (ie F-35).

All the fighters it actually builds date from the pre-merger McDonald Douglass days. Not that it’s actually building any of those at the moment as it’s into week 6 of a strike at Boeing Defense.

When did BAE last design a new fighter? The Typhoon in the 90s.

When did Boeing/ McDonald Douglas) last design a new fighter? The F18 in the 70s…

‘Companies build aircraft, not countries.’

This is just plain wrong. Boeing is the main contractor, but just like with all other modern American fighter projects, the effort is national and the other major companies will be given work. I’ll add that Boeing was a partner in Lockheed’s F-22, and that the Super Hornet and F-15EX are very significant redesigns. Additionally, we should acknowledge that BAE’s work on the Typhoon was part of a collaborative effort – you can hardly attribute it purely to BAE.

I’m not quite sure what’s driving the jingoistic fervour here. Why should we claim that an aircraft that again will enter service more than a decade in the future, that has yet to settle on a design, has yet to fly a combat demonstrator, being developed by nations with limited experience in developing ‘world-beating combat aircraft is going to be ‘world-beating’. Especially when nations with larger economies, more experience and more resources are significantly ahead of the GCAP partners.

That you don’t think companies build aircraft is hilarious, even in autocracies like China and Russia the governments don’t build aircraft, its companies.

And no once company can do all the work, it’s called sub-contracting. 🤦🏻♂️

I’m not quite sure what’s driving your reality distortion field, but it’s hilarious to watch.

‘it’s called sub-contracting.’

And who do they subcontract to…hint, it’s not just smaller companies.

But that’s not the point of the argument. Again, I ask you:

Why should we claim that an aircraft that again will enter service more than a decade in the future, that has yet to settle on a design, has yet to fly a combat demonstrator, being developed by nations with limited experience in developing ‘world-beating combat aircraft is going to be ‘world-beating’. Especially when nations with larger economies, more experience and more resources are significantly ahead of the GCAP partners.

As I usually find with idiots, they don’t bother reading what is actually posted in their eagerness to post a vitriolic response. They don’t learn to stop digging deeper the hole that they’re in. 🤷🏻♂️

I never said that Tempest will be “world beating’’, etc, etc, etc.

I simply stated the facts

• aircraft companies design and build aircraft, not governments

• Boeing has never built a stealth jet

• All the military jets built by Boeing were designed in the 70s

• BAE has recent experience of designing and building jets with participation on Typhoon and F35.

Based on practical experience, BAE has clearly greater, more recent, experience than Boeing.

I’d recommend reading back through my comments then, because I explained my response to those facts above.

If you thought what I wrote was particularly vitriolic, I suggest taking another look at what that word actually means.

Have a great day.

“ There’s a slight difference between the US, doing the vast majority of design and construction on the F-35”

Hmme well BAE designed a lot of the F35 including the stabilisation system developed at RAE Bedford.

They do produce the tail sections – quite a hard part of the plane.

It is arguable that RR should have provided the powerplant but that was probably too far down the NIH track.

We build all the wings for a wide variety of planes in the UK – again the hard part.

Radar and avionics we’ve always done well on – better than most realise.

The British designed components of the F-35 are about 15-30%, depending on the claim. I think it’s fair to characterise the vast majority of design and construction work as American. I believe some parts of the BAE work was also undertaken by the American, rather than the British branch of the company, but I may be incorrect on that point.

But I’d go back to my initial point – how can we describe an aircraft that is yet to fly a combat demonstrator and is still a decade away from service as ‘world-beating’? I’m sure Tempest will be very good (as I said above), but I don’t think it’s at all fair to assume that the coalition will produce something significantly ahead of either the US or China.

Because it is a fresh design that has been produced at speed and won’t incorporate technology that belongs in the 1990’s.

The flaw with Typhoon was that EAP was a 1980’s design and that the design and delivery was then strung out over decades so inevitably it is very technologically dated.

‘Because it is a fresh design that has been produced at speed and won’t incorporate technology that belongs in the 1990’s.’

The issue there is that the rest of the world will also have moved on from the 1990s. For example, we know that the US is embracing variable cycle engines, and China are likely doing the same. I believe the SCAF partners intend to do the same. On the other hand, the GCAP partners will not be pursuing that technology in favour of a cheaper and more conservative system.

“The issue there is that the rest of the world will also have moved on from the 1990s”

Picks up on the wrong point.

The point is that it is developed at speed – something that LM have been the poster child for not being able to deliver having successfully put together the US equivalent of the Tornado/Typhoon programs with all the turgid collaborative problems that reproduced.

Sometimes it is smarter to move past an immature technology to get something done. Variable cycle engines are an idea under development and nowhere near mature or cost effective. Also the question is why you would actually need them unless the idea was to reinvent the camel by committee. A current jet engine is developed to operate optimally at one bypass ratio which means one flight condition as per Concord it was Mach 2.2 and it wasn’t much use at flying at any other speed. Olympus was an amazingly compact engine for its power output. So variable cycle is only really needed if you need to be able to sit at a slow cruise efficiently as well as to sprint efficiently. The solution here is to leave space so that variable is possible and in a large frame that is easier than in a small frame.

I picked up on the point you made. If you don’t want me to talk about it, please don’t add it into your comment.

I agree with what you’ve written, and I agree with the decision not to go variable cycle, and likewise, not to go tailless.

That said, the disadvantage of going conservative is that the aircraft produced is generally less capable overall, which is the part relevant to the discussion around ‘world-beaters’.

Again, I’m not saying that the Tempest will be a bad plane. I expect it to be very capable. I’m also not saying I’d prefer the design to be more radical – I think the current plans have the right balance of capability vs cost/timeline. But there is a tradeoff, and larger powers like the US and China could afford to mass produce a more capable design in today’s climate.

Perfection is the enemy of the good.

F22 was, for its time, perfection. But it was so expensive that the numbers ordered are too low.

So I do see why GCAP would go down the proven tech route as there is then a chance we might actually get an uplift in frame numbers rather than pour all of the money into a huge R&D project.

R&D cost is mostly time driven so, in the simplest case, the longer the R&D cycle is the more it will cost keeping big teams busy. The reason for that is that solving one tech challenge may take a long time and in the mean time the other tech teams will need something to do.

Fully agree with all of that.

Brilliant. Feels like there is momentum just wonder if it is enough to satisfy Japan.

The words ‘revolutionary’ and ‘evolution’ fill me with dread when you look at how ambitious the timescales to deliver this aircraft is! All the same, wish them well and fingers crossed all is well behind the scenes.

With these things you are better off moving fast rather than getting into clever overthinking debates

If the plane has weight/power/space margins then problems can be solved.

Imagine being the Chef for that bunch !