The vessels will be constructed by “British-led teams”, Defence Secretary Ben Wallace has announced.

While international companies will be invited to work in collaboration with UK firms, “the successful manufacturing team must be led by a British company”.

“This will have a huge impact on the local economies across the UK where shipbuilding is a prominent feature. Hundreds of highly skilled jobs will be created as a direct result of today’s announcement, with many more in small and medium sized enterprises throughout the supply chain for the new builds to follow over the next few years.”

Defence Secretary Ben Wallace said:

“Shipbuilding has historically been a British success story, and I am determined to revitalise this amazing industry as part of this Government’s commitment to build back better. The Fleet Solid Support warships competition will be the genesis of a great UK shipbuilding industry, and allow us to develop the skills and expertise for the shipyards of tomorrow.”

According to a statement from the Ministry of Defence:

“The Fleet Solid Support ship competition will build on the success of the Type 31 programme, which will be built primarily in Scotland and is expected to support 1250 highly skilled jobs and 150 apprenticeships across the country.

The Fleet Solid Support warships competition will be designed to challenge the shipbuilding industry. The goal will be to build ships fit for the future, while boosting homegrown skills and leading to a highly competitive shipbuilding industry.

The warships will incorporate next-generation technology with a purpose-built design and will eventually support HMS Queen Elizabeth and Prince of Wales as part of the Carrier Strike Group, which will undertake its first operational deployment next year. Today’s announcement follows a period of market engagement and a clearer understanding of how the strike group will operate and will allow the MOD to consider a broader range of ship designs. As well as setting out requirements for British involvement, the Fleet Solid Support ship competition will set targets to ensure industry delivers on time and at pace.”

The build competition was initially offered internationally, meeting strong criticism from all sides of the political spectrum and even the UK Defence Journal. The tendering process for the ships was even suspended last year, with some suggesting the process was being restructured to better favour British bids.

Better late than never?

Earlier in the year, The National Audit Office released a report titled ‘Carrier Strike – Preparing for deployment’, the report examines the MoD’s management of the programme since 2017 and the risks towards achieving Carrier Strike’s full capabilities.

Under the Carrier Enabled Power Projection concept, the operational freedom of a carrier group relies on support ships providing munitions and stores where and when they are needed. However, delays are posing risks to the programme say the NAO.

According to the National Audit Office:

“The Department has been slow to develop the solid support ships which are crucial to operating a carrier strike group. Carrier Strike relies on the sustained availability of munitions and stores, such as ammunition and food. However, the Department has only one ship able to resupply a carrier group, which slows the tempo and reach at which this can be done. It has long been aware that this will restrict the operational freedom of Carrier Strike but has not yet developed a solution.

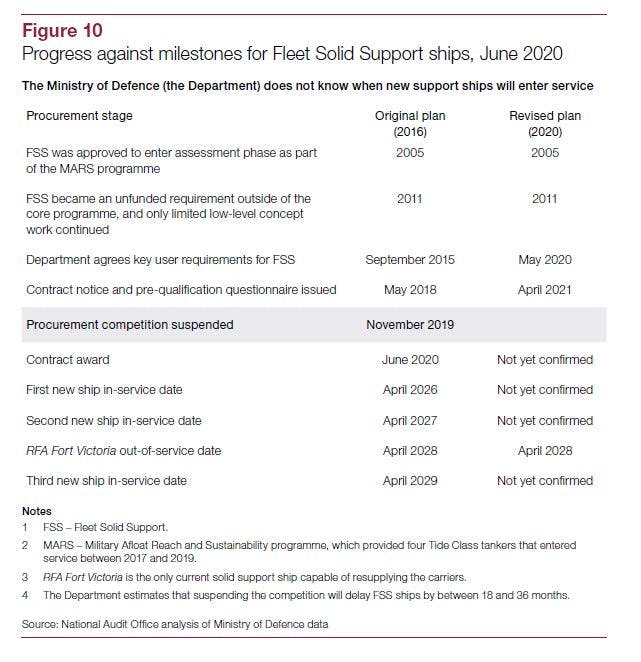

In November 2019, the Department stopped the competition to build three new support ships due to concerns about value for money. It believes this will delay the introduction of new ships by between 18 and 36 months, making it uncertain the first new ship will be operational before the existing support ship leaves service in 2028. The Department will also incur additional maintenance costs while it uses its existing support ship as an interim solution.”

The Department has long known that deploying Carrier Strike will depend on two types of support ship:

• tankers supplying oil and water; and

• solid support ships, carrying food, ammunition and general stores.

In April 2020, the MoD was reviewing its options and the impact on the delivery schedule. It has recognised that achieving full capabilities of a carrier strike group depends on the new support ships being available from the mid-2020s.

The NAO say that the MoD will need to assess the impact of any delay when it considers whether it has met the final CEPP programme milestone for full operating capability in 2026.

“In the meantime, only one of the three current Royal Fleet Auxiliary solid support ships is capable of resupplying the carriers. RFA Fort Victoria entered service in 1994 and is due to retire in 2028, having already been extended beyond its 25-year service life. The Department has allocated £2 million to modify RFA Fort Victoria so it can replenish the carriers at sea and in 2016 budgeted up to £42 million to operate the ship to 2028. Having only one support ship with limited cargo capacity slows the tempo and reach at which the Department can replenish a carrier group. In addition, the Department will have restricted options for deploying the carriers for much of 2022 because RFA Fort Victoria will be unavailable due to major planned maintenance work.”

However, the MoD now expects there will be a delay of between 18 and 36 months to the new ships entering service, meaning the first ship would be operational between October 2027 and April 2029.

Where might they be built?

Belfast appears to be the favourite to construct the vessels after InfraStrata, the firm that bought Harland and Wolff, signed a memorandum of understanding with Navantia.

Navantia say that the agreement with InfraStrata at the Harland and Wolff shipyard in Belfast will allow them “to work on the Fleet Solid Support Ships and other offshore projects”.

Navantia are participating in this tender in partnership with BMT, their design is pictured at the top of this article).

The rationale for this, say Navantia, is that “BMT has proven naval design and engineering capability, including support ships for the UK (Tide Class) and Norwegian (HNoMS Maud) defence ministries, and as design partner in the Carrier Alliance”.

The firm adds that “through the combined strengths of their partnership, the Navantia-BMT proposal assures low technical risk, budget viability and timely delivery”.

Sounds like we have a strategy of build everything we can in the UK …

I’m no expert, but even I know that it’s crucial these three ships need to be ordered as soon as possible….

Such a shame they got rid of Fort George, we could really have made use of her

Now!

And kept Fort Rosalie and Austin, which are older and less capable.

Agreed the scrapping of Fort George was madness just like selling Largs Bay for peanuts. Laid up for a year or two during difficult times yes, but getting rid of both those vessels was lunacy. Even more so when you consider they then proceeded to waste more money than then they actually saved, in the abortive catobar conversion of PoW.

But just wait that moron Cameron will actually get a knighthood!

Having Spanish Navantia build the ships with a token contribution by HW is not the answer. The ships need to be built in a UK shipyard that has a long term future so that the necessary investments are not wasted.

Cammell Laird is the obvious choice. They could either build the BMT or Bae designs. Other UK shipyards could supply blocks just like they did with the aircraft carriers.

Navantia will transfer technology, know-how and manpower to H&W who will use it to help build the Arctic and renewable infrastructure.

Logically you are right. But politics come into play. Navantia must have received a nod that leveraging the H&W name and bidding is worthwhile. I am cynical enough to think that this is a Westminster bribe to the Ulster Unionists to rein themselves in as they gradually lose their grip on power in NI.

Wasting everyone’s time if they think giving this work to Scotland will stop the inevitable…The Rubicon has been crossed up there and they’ll be off, ship building industry or not.

..Give the work to yards elsewhere in the UK, where it will actually be appreciated for the jobs it will secure.

Agreed I can see this finally getting off the ground just as its inevitable that Scotland votes to leave and then further expensive delays trying to relocate them assuming by then there are such places available. Ironic if the only place available is in Europe by then. We need a UK wide capability or we lose all leverage by playing into the hands of the Nationalists with problems of practicality taking orders away once given while any move to spread it about as its more being focused there will be exploited by them as an attack on Scotland by not giving them their then expected historical share. Orders need to be weaned off them while we still can.

An interesting take on “we” and “them”.

If Scotland votes to leave the UK and down the line (because it won’t happen overnight) both Scotland and rUK have to divvy up stuff then ship building will just be one strand of many that will need to be untangled. It will be in both country’s interests to try and play nicely while all this is sorted out, the company that is getting paid to build the ships will still be getting paid to build the ships…. it might be in a different country for a short while but it will be just up the road and it will then give BAE or whoever time to set up their new facility in Barrow or wherever.

I don’t think ship building will be the biggest problem for either set of governments in the event of an indy vote.

Play nicely with them?

Fuck that…put them on their fucking knees, seditious wankers.

Makes you wonder why people would want to vote for independence in the first place, eh mac?

Hey, you’re the ones trying to destroy something built up over 300yrs of blood & treasure, not the rest of us.

I don’t think it is inevitable that the Scots will vote to leave. In the new year the problems and opportunities afforded by Brexit and any trade deal with the US will become clearer. The UK Internal Market legislation formalises tariff free trade between the constituent nations of the UK. Nicola Sturgeon’s recent proposal to put tariffs on goods from NI is a first shot in a what will be a protracted political battle. Boris is proposing to build a bridge between Scotland and Ulster; enabling an historic reunification of the Gallic peoples perhaps; and certainly encouraging economic growth in Scotland, NI, Ireland and the North of England. Are we in fact seeing the emergence of a federal UK? Replace the House of Lords with Senate of proportionally elected college members based on area from the 4 home nations and repeal the Act of Succession and you can offer the Scots an attractive alternative to being a new minor state in a struggling EU.

Quote from above, “This will have a huge impact on the local economies across the UK”

The question is, why have successive govts ignored the benefits of supporting the British manufacturing base and for the last 25 years +/- placed nearly all major defence contracts aboard ?

Let me give you just ONE example.

The £2bn contract for 8000 Army trucks in 2005, was the single biggest truck order of the decade. Blair wanted to show he was a “Good European”. Rather than award the tender to the UK firm he adhered to the EU’s Procurement Rules. The vehicles would have been built in Birmingham by LDV and the program would have provided work for 140 other UK suppliers. Instead Blair gave it to Gemany’s MAN/VW. But our EU partners utterly ignore EU Procurement Rules and unlike the UK they have protected THEIR manufacturing industries. The French, German, Italian, Dutch, Swedish, Spanish armies all drive trucks built by their OWN industries.

Well I didn’t vote for that idiot.

When do we Brits ever put ourselves first?

Even on Brexit currently there are MP’s criticising HMG negotiations with the EU over fears of no FTA. As to get one would effectively mean HMG caving in and allow EU access to fishing, ECJ primacy, and a “level playing field” which translated means hamstringing yourself and accepting EU restrictions, which are designed to stop the UK realising its potential because the EU do not want a competitor on their doorstep.

All to punish the UK for daring to leave, and in the process cutting off their own noses to spite their own face, where’s a FT deal with no strings would be beneficial for everyone.

Judging by the wailing from the opposition benches and the revolt the other day over the bill designed to protect MI5 staff in carrying out their duties protecting this country, what has changed?

What you have just described is the usual political answer to any problem, over promise, under deliver, and when it all goes horribly wrong, ( I would use the expression tits up, but this is a family friendly website!) then pin the blame on anyone you can rather than taking any form of responsibility. And the man Johnson is a past master at that, just ask any of his former wives or mistresses or any of his previous employers.

However, I can see a glimmer of hope in this one, with the distinct possibility that the ships will be built here. I would even back Navantia leading providing that the bulk of the work is done by companies in UK, but I bet they don’t think to write a tight enough contract. I’m not holding my breath because any one in Whitehall can snatch defeat from the jaws of victory and probably get promoted on the back of it.

In the case of ship building that’s not the case, 1 order has gone overseas all others have been UK. Its debatable if that particular order could have been delivered by UK yards at the time.

BAE is quick to list UK suppliers in the Type 26 program but is coy when it comes to reporting what is actually being built in the UK. The bulk of the Type 26 equipment is being manufactured in Europe. Take the steel for example on the BAE list of suppliers the source of the steel is Dent of Bradford. But Dent is only the wholesaler. The 20,000 tonnes of steel is actually Swedish. Rolls Royce is listed as the supplier of the turbines and generators but these are all being built in Germany.Compressors Germany. Water systems and pumps Denmark. Control systems, Raytheon US and Germany. The list goes on.

Cameron called the Ajax program the biggest defence project for decade and then proceeded to award it to Spain rather than select the BAE Newcastle built CV90. The Ajax program is touted as British built in South Wales, But the steel is all Swedish. The engine and gearbox German. The gun French, The 1st 100 vehicles will be entirely built in Spain. The remaining 489 hulls will be fabricated in Spain. S Wales is just assemblying items built in Europe.

The point is successive Labour and Conservative govt have run the UK manufacturing base into the ground , to placate Eurocrats in Brussels.

The hulls could still be built in Spain, so this news is STILL premature.

I would image there would be will to repeat the success of the T31 which has already garnered significant overseas interest from 30 countries and lead to Babcock investing in a frigate line in Rosyth to increase productivity. So I think we’ll see 2 competitive organisations formed BMT/Navantia/HW and BAe/CM. HW leading the former and CM the latter to meet the UK built criteria.

I think I’d rather see these ships built in Spain then Scotland.

I don’t like the quote ‘British led teams’. Sounds full of holes.

British yards would be more clear and supportive.