General Dynamics has been awarded a $55.9m contract for 18 missile tubes for the US Navy and the Royal Navy.

According to a contract notice, work will be performed in Quonset Point, Rhode Island, and is for the manufacturing of 18 missile tubes in support of the US Columbia class fleet ballistic missile submarines and the UK Dreadnought class ballistic missile submarines. The notice is displayed below.

“General Dynamics Electric Boat, Groton, Connecticut, is awarded a $55,904,934 cost-plus-fixed-fee modification to previously-awarded contract N00024-17-C-2117. Work will be performed in Quonet Point, Rhode Island, and is for the manufacturing of 18 missile tubes in support of Columbia-class fleet ballistic missile submarines and the United Kingdom (U.K.) Dreadnought. Work is expected to be complete by May 2028.

This is a joint U.S. and U.K. common missile compartment program, and the modification is funded with U.K. Foreign Military Sales funding. U.K. funding in the amount of $12,354,112 will be obligated at the time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, District of Columbia, is the contracting activity.”

Work is expected to be complete by May 2028.

The programme faced some issues in 2018 after faulty welding was identified on missile tube systems, the issue was later resolved and is understood not to have impacted on the Dreadnought programme.

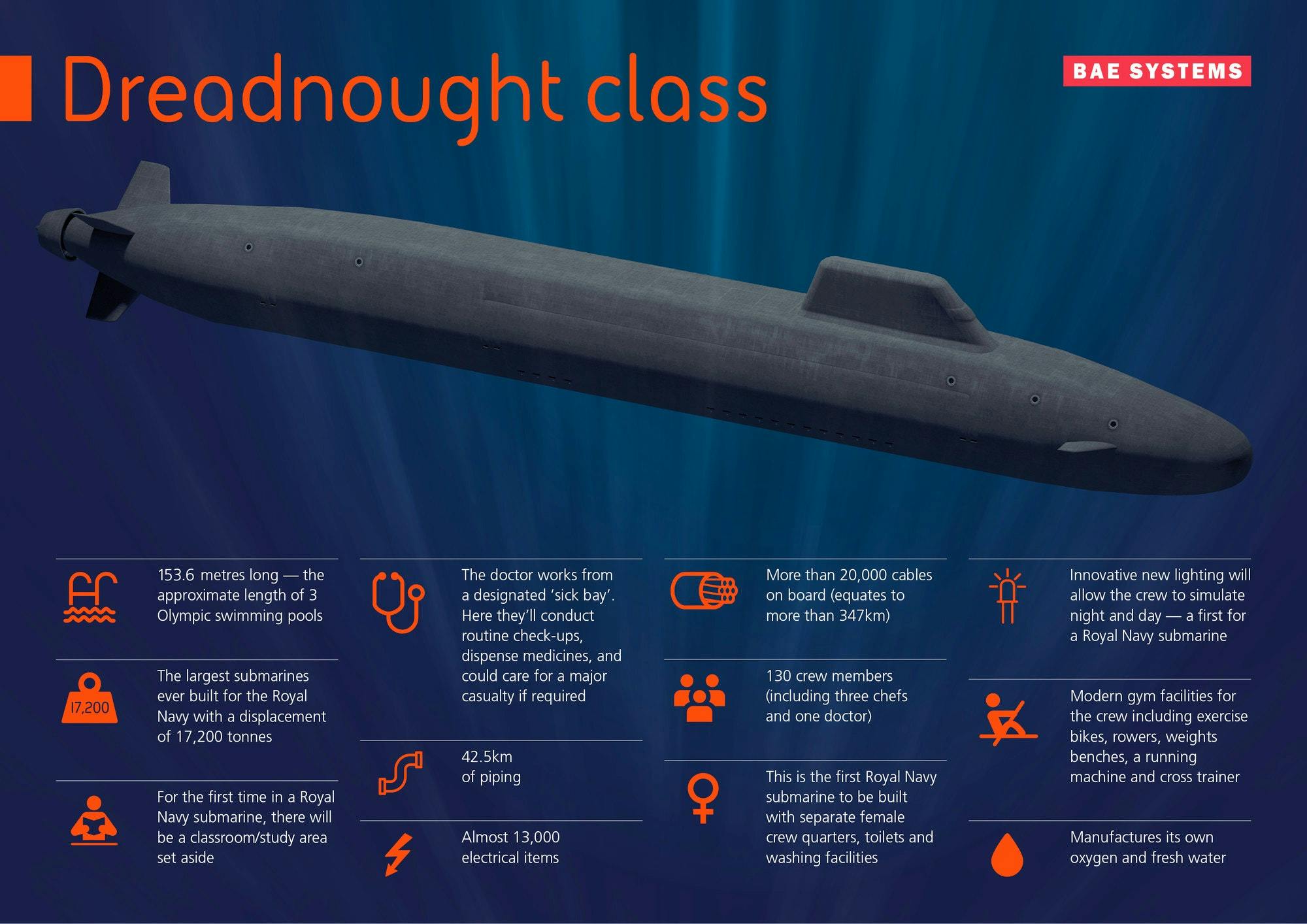

The Dreadnought class will replace the Vanguard class submarines from 2028 onwards and will host the United Kingdom’s nuclear deterrent.

Certainly seems like the newest Dreadnought class will be the nicest submarines to live on for the crew. No doubt to improve recruitment.

The current bombers are the most luxurious so far by quite a stretch.

It seems you are on your last legs now?

To bring forward procurement projects is the best best way to boost the economy, once the lockdown is over!

I would love to know how they make 18 Steel Tubes cost $56,000,000.

It can’t be rocket science.

Err, actually it is 🙂 . Well sort of.

Joking aside these are highly stressed components. They’ll be exposed to max dive pressure plus the extra stresses of the launch which I believe involves considerable compressed gas pressure to accelerate the missile from the tube sufficient to get the missile out of the water prior to motor ignition.

They’ll also have to be able to do it reliably for 20 to 30 years whilst being periodically exposed to corrosive sea water. So you’re looking at some pretty expensive steel alloy, likely to be difficult to weld to the necessary high standard and then there’ll be considerable inspection and documentation costs – not unlike the certification regime in the civil aviation industry. None of which considers the control and hatch actuation systems which will include links to the launch control system which I guess would be constructed to thre highest standards to ensure reliable and safe launch cycles.

Cheers CR

Indeed. All submarine components are expensive because they’re painstakingly constructed, because having them fail is really, really not acceptable.

Yeh, a bit like a wing falling off an aeroplane – a serious ‘Oh bother!’ moment…

Crayons……….

Harold…..crayons

He has reappeared as Iqbal on STRN.

His is certainly the same style of postings!

Ah iqbal once more, this saddo, Harold/Iqbal become very tedious and stupid with their pathetic efforts at baiting. If that’s all they have then I suppose good luck to them……sad though isn’t it.

Iqbal, I forgot that one until you mentioned.

That is correct, just the same old sad rantings!

Absolutely magnificent boats , best of British tech , housed in the purest waters in the British isles , ??????????? hopefully lessons learned from Astute class can avoid any build issues.

A few things, have you noticed the thinkness of the deck plate, it must be about 4-6 inchies thick (100-150mm) and the size of the screw bolts. That’s one big Allen key needed.

I wonder if anyone as noticed the £600 million investment into Devonport for the 10 Facility Dock to be upgraded to carry out maintance for the new Dreadnought subs.