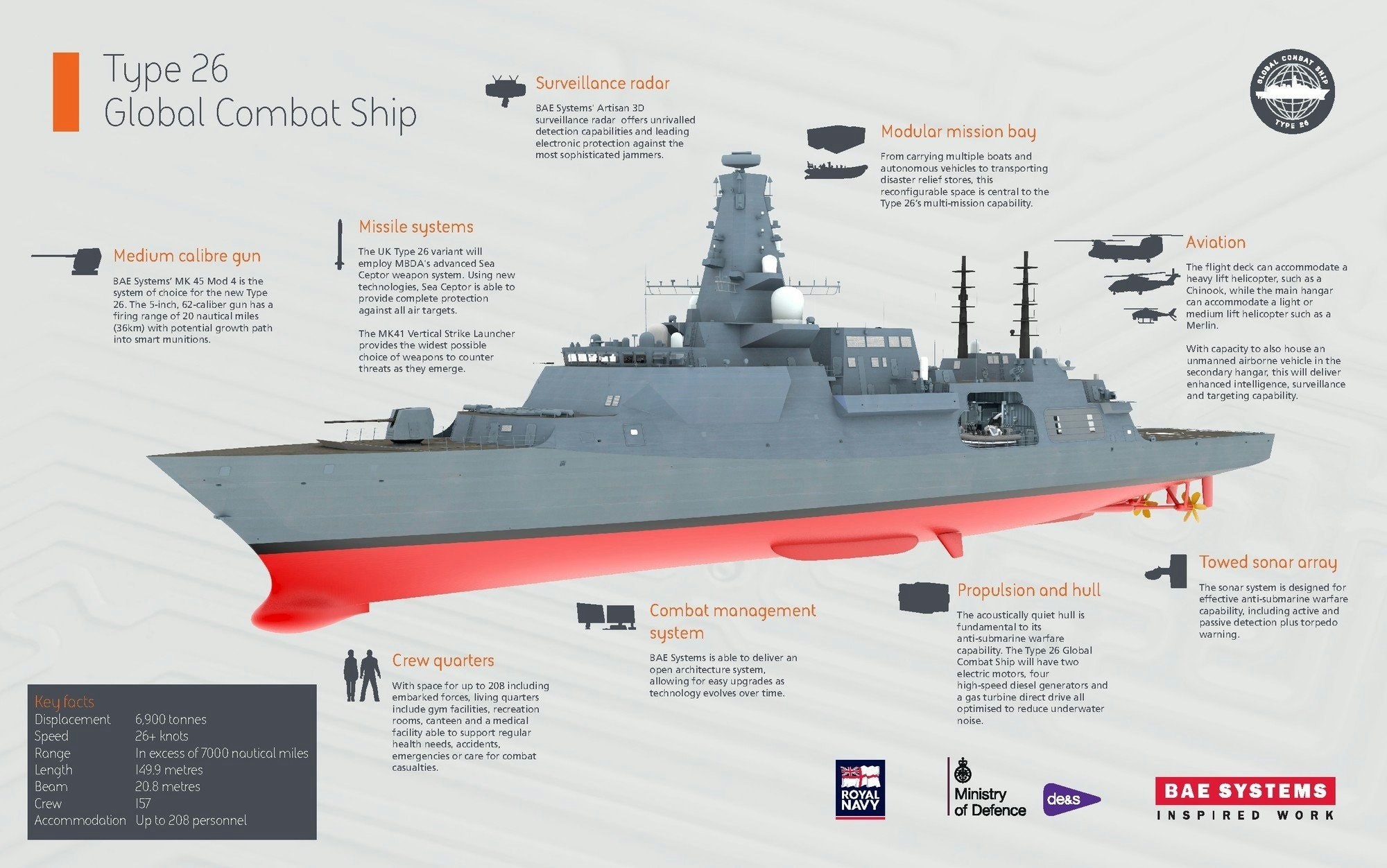

Rolls-Royce has signed two contracts with BAE Systems to supply low-noise propellers and mission bay handling technologies for the UK Royal Navy’s new Type 26 Frigate.

The contracts cover the first three ships – the first of which is currently under construction at the BAE Systems shipyard in Glasgow.

The Type 26 is designed with modularity and flexibility in mind and a key feature which sets it apart from competing designs is its mission bay. The Rolls-Royce Mission Bay Handling System, will enable efficient movement of craft and containerised mission packages within the mission bay. It also features a launch and recovery capability say the company.

Each ship will feature two Rolls-Royce fixed bolted propellers, designed for extremely low underwater-radiated noise, suited to the ships’ key role of anti-submarine warfare.

Don Roussinos, Rolls-Royce, President – Naval, said:

“The Royal Navy’s Type 26 frigates will be globally deployable, multi-mission warships capable of undertaking a wide range of roles. We’re proud to be supplying our pioneering Mission Bay Handling System, which will ensure flexibility and adaptability throughout the life of the ships, whatever their future mission.

Our propeller technology will once again provide the Royal Navy with the all-important combination of high propulsive efficiency and low underwater-radiated noise signature to fulfil the essential anti-submarine warfare role of these ships.”

Nadia Savage, BAE Systems Type 26 Programme Director said:

“The Type 26 Global Combat Ship is a next generation anti-submarine platform that will provide great flexibility and agility for the Royal Navy. With Rolls-Royce contracted to supply the low-noise propellers and mission bay technologies, these vessels will have the highest standards of capability and adaptability that the Royal Navy needs to continue to protect UK national interests.

Manufacture of GLASGOW, the first of the three contracted City Class Type 26s for the Royal Navy, is progressing well in Glasgow, and these contracts are further evidence of the great momentum that is driving this project forward.”

Rolls-Royce is delivering the majority of the propulsion system for the Type 26. Power will come from a single MT30 gas turbine, providing direct drive through a gear box, and four MTU Series 4000 diesel generator sets from Rolls-Royce Power Systems.

I’m pretty sure the propellers are not even made in Britain but a Scandanavian country I seem to recall. The Diesel engines will also not be built in Britain. This report completely ignores this fact. These are very important parts which we should be making for ourselves, not using our Royal Navy to keep foreign manufacturing going.

I think we have to get away from the idea of building absolutely everything here. We have to accept that in recent decades we have let other countries invest more and develop better products. Now that doesn’t mean we should buy everything from overseas either and I am fiercely critical of the UK Governments propensity to buy anything as long as its foreign. Like tankers, fighters or armoured vehicles for example. But when a British company like RR buys and invests in an excellent German large diesel manufacturer (MTU) and Scandinavian and American propeller makers then guess where the profits return to? The US Navy chooses the MT30 because its the best. They also choose BAE Systems (albeit based in the USA as well as UK) and that is from one of the most protectionist countries in the world….

So sometimes ‘buying British’ can also mean ‘made elsewhere’.

Just looking at that crane arm, I was a Combat Support Boat op in the falklands and I was based on the MV Lycaon . My boat was kept on the ship and was lowered into the water and back onto the deck at the close of play. I had a 4 fingered metal strop shackled to the 4 pick up points culminating in a metal ring. I would pilot myself under the crane hook and then with a bit of niffty footwork hook up the boat to the crane. Simple, easy and any crane can do the job. I would sail around the boat and drive into the current (even in bad weather) and be hooked up and out of the water in under 30 seconds. That contraption looks somewhat complicated.

I was thinking the same – why not just have a gantry crane that extends out to the side. Surely this is known technology that is simple and works well. It also means you can deploy both sides if needed.

Not sure why we always have to go for the expensive/complex option.

“why not just have a gantry crane that extends out to the side.”

Even more perplexing because I’m sure that I read somewhere a while back that one of the features of the T26 mission bay was an overhead crane in the mission bay that could reach out to the side (either side?) of the ship with enough reach and structural integrity at full extension to allow a T26 to self-load standard ISO containers into its mission bay if it ever found itself picking up (or presumably more likely offloading) at a port without suitable local crane facilities. Surely that would do the job here just fine?

Excellent insights Farouk, thanks for your service to the country mate. But I think if they went for a low tech easy to work solution then BAES could not charge guzillions for the contraption.

Agree it all looks ridiculously complicated and expensive. Also therefore likely to be prone to failure in the harsh maritime environment.

What sea state will these contraptions work in anyone know. Quite important as type 26s can expect to spend a large part of their life in the North Sea or Atlantic where things get choppy.

I quite agree Mr Bell. I can’t imagine that enormous A-frame can rise and fall with the waves/rib in anything more than a calm sea.

A piece of steel cable over a derrick would be far more flexible and far cheaper.