Engineers from BAE’s submarines business have developed new Personal Protective Equipment for NHS staff on Covid-19 wards.

The firm say that in just 11 months the project has gone from concept to the hood gaining Health and Safety Executive (HSE) approval for use during the pandemic.

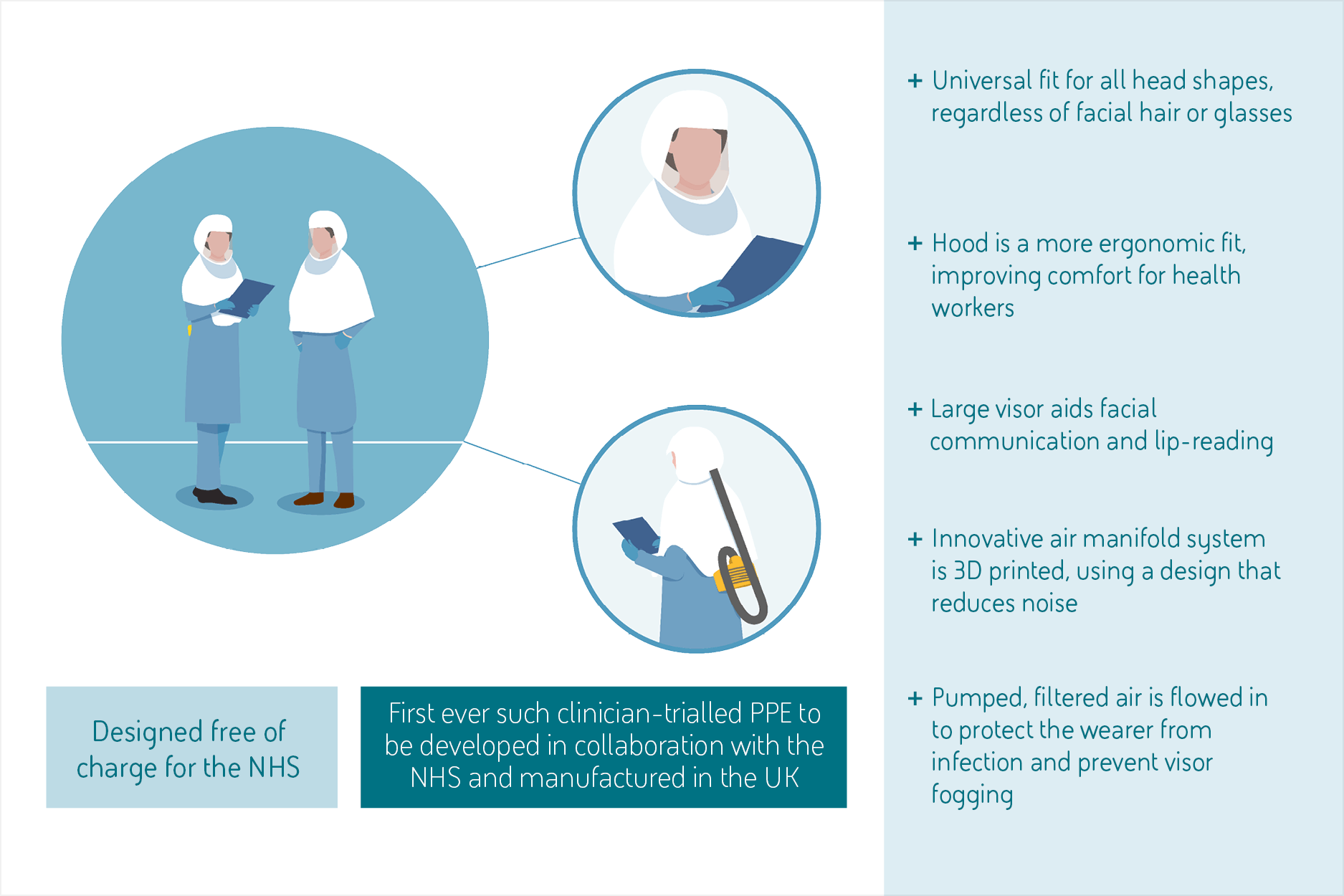

“Together with Lancastle, we have designed the hood free of charge, with the hoods being rolled out to hospital wards in Lancashire and South Cumbria over the next few weeks. Developed to replace current PPE hoods, which were created for an industrial rather than a clinical environment, the Morecambe Bay Hood is less expensive, is fully cleanable, reusable and offers greater protection and comfort to healthcare workers as the hood is suitable for all face shapes and sizes.

The design – a full-face protective hood delivering a continuous stream of clean filtered air – significantly reduces ‘fogging’ and aids improved communication and empathy between healthcare staff and patients because facial expressions can be seen more clearly and lip-reading is easier.”

The below image is via BAE Systems.

Stuart Hosking-Durn, Head of Resilience and Patient Flow for UHMBT, was quoted as saying:

“The dedication of our frontline workers has been instrumental in fighting COVID-19, but the Morecambe Bay Hood will be an absolute game-changer for us as we continue to care for patients, significantly improving comfort, durability and communication. It’s a UK success story, with our thriving tech sector supporting our frontline workers as they help our country to emerge from the pandemic. The hoods could be rolled out more widely across the UK and could enable the NHS to treat patients with infectious diseases more safely.”

Well done BAE 👏.

Brilliant British design and engineering providing solutions to the world. Well done all at BAE. On a flippant note, Space Odyssey 2001 the inspiration?

So thats what they have been doing down the DDH. Here’s me thinking they were building submarines.

ONLY ISSUE is like most Projects of BAEs there 12 months late, Southampton university had a hood up and running in 8 weeks.

The difference is with this one is that it has been through clinical trials and gained approval from the HSE which is not an easy task to do. This is a really good example, amongst many, of why we need a really healthy engineering and manufacturing sector in this country. We are beginning to see more companies move back from Asia to Europe because of what has happened during Covid, lets hope they don’t all get bought up by US and Chinese companies…!!!.

Yes, hopefully we slowly bring back engineering. As is a covid variant F++ could occur in china or elsewhere breaking supply chains esp if China locks down. Or we have another Suez blockage.

Interesting for above what materials is the hood made from is it something akin to goretex to let out moisture but not let in viruses etc.

How do you manage heat dissipation? Can we put a chiller in the filter unit supplying the clean air?

This is very similar to semiconductor clean room garb from the 90’s/early 2000’s where wafers were exposed to the clean room environment, except in reverse…

The semicon helmet had an inward flow of air through a half height face shield driven by an extracting system that exited through a HEPA filter…

Here they have just reversed the flow, so a HEPA filter input, likely used a shower manifold above the faceplate to use the inflow air to keep it clear and positive pressure in the helmet as a consequence of the flow. It doesn’t say if they use gore-tex as the helmet fabric, but it would make sense to ensure viruses stay on the outside – no through fabric wetting/virus transmission in case someone coughs/gets blood or other fluids onto the fabric. Gore-tex is also standard cleanroom fabric too, so no leap of imagination required.

I was talking with a friend about this & we were wondering why this hadn’t been introduced as it was a trivial exercise to switch from keeping particles in to particles (ie bacteria/viruses) out. Seems like it was the approval process (11 months!)

BTW, heat dissipation will be from the airflow with normal sweat evaporation, cool room air helps as will the input air being blown down in front of your face. Increase the flow for more cooling.

Too true… We need to bring the engineering and manufacturing base back…

Fair play, useful and good PR for the company.