A full scale durability test airframe of the F-35A aircraft has successfully completed its third life testing say BAE.

The company say that this is equivalent to 24,000 hours of ‘flying’, and was conducted in a unique testing facility at BAE Systems’ site in Brough, East Yorkshire.

The airframe, known as AJ-1, is representative of the F-35A Conventional Take-Off and Landing (CTOL) variant of the jet.

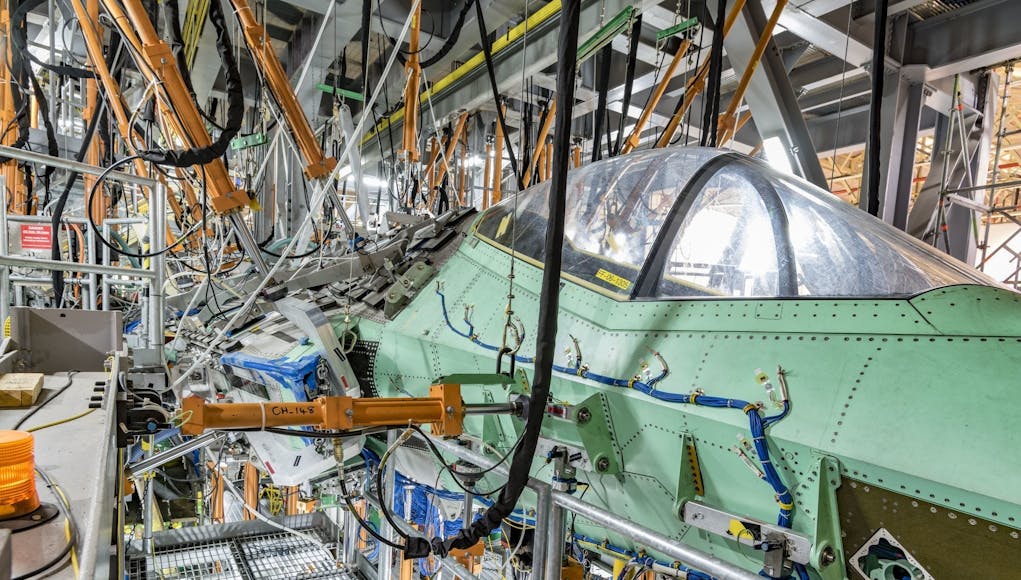

While in the 350-tonnes structural test rig it has been subjected to and tested on the range of loads it would experience in actual flight, with durability tests carried out to simulate real life fleet usage based on projected operational requirements.

BAE Systems’ durability test rig is the only one of its kind in the United Kingdom and it has supported the testing of AJ-1 since it arrived in Brough in 2009. It is fitted with more than 20 miles of wiring, 2,500 strain gauges and 160 loading actuators which are attached to the airframe during testing.

Kathy Nesmith, F-35 Joint Program Office Airframe Team Lead, said:

“The F-35 programme requires a service life of 8,000 flight hours. This is verified through durability testing to two lifetimes or 16,000 hours. Completing third life testing on the F-35A durability article will provide us the data to enable the warfighter to maintain and sustain this aircraft beyond 2050.”

Matt Edghill, Lockheed Martin’s F-35 Structures Development Director, said:

“The 5th generation F-35, with advanced speed and agility, pushes the boundaries of engineering and physics. This durability testing confirms the airframe will perform in and withstand the demanding environments it will experience throughout its operational lifetime. Completion of the F-35A’s third lifetime test gives our programme great confidence in the aircraft’s strength and durability for decades to come.”

Andy Prendergast, Operations Manager for Structural and Dynamic Test at BAE Systems, said:

“This testing has pushed the F-35A airframe to its limits to make sure it will fly safely and effectively throughout its lifetime. We have continually checked the airframe for any signs of stresses and strains and reported findings back to the programme so structural improvements could be made, if required, long before any issues appear in the flying fleet.”

Both the F-35B and F-35C durability test articles have completed 16,000 hour second life testing and are continuing with additional testing to maximize the life of the aircraft according to a release.

The F-35 is the latest in a line of aircraft to have been tested at Brough which includes the Buccaneer, Harrier, Hawk and most recently, Eurofighter Typhoon, which continues to be tested at the site.

The thousands of high level technical jobs created in the UK as result of our being the only tier one international partner in this US led program makes this one of the best investments this country has ever made.

We are playing a substantial role in every single F35 manufactured.

Very true.

It should have been a condition of the deal that we build our own F35s.

Another role we play in the F-35 programme that rarely gets any media coverage. And I think this is the only such test rig for the F-35.

Unless they can say “because brexit” the media won’t care about it.

The F35 project is very good economically for the UK, the decision to be a level one partner was a wise decision.

On a personal note: always great to see Brough at the forefront of interesting work. My grandfather worked on the timber hulled flying boats of the 1920’s there and then in other roles, whilst my father worked there during WW2(they lived in the companies ‘Blackburn Avenue!).

It’s just a shame we have to send the engines to Turkey for maintenance. Not exactly a stable government at the moment. Would have liked Brough to build the entire airframe as the Italians are doing. Then perhaps we could have a few more than we have at the moment. I still think we need to see the true cost of the F35B, even the Defence Select Committee couldn’t get an answer from Lockheed Martin & Ministry of Defence on how much the next tranch would cost.

Agreed on all points.

Turkey: vital bridgehead to the Middle East yes but it does seem that the current regime are clearly moving away from their previous long held desire for intimacy with the West.

Most countries build aeroplanes in their own countries (eg. India with the Hawks), bu then again most countries are not waging war against their own industries like Britain is, and has been for decades.