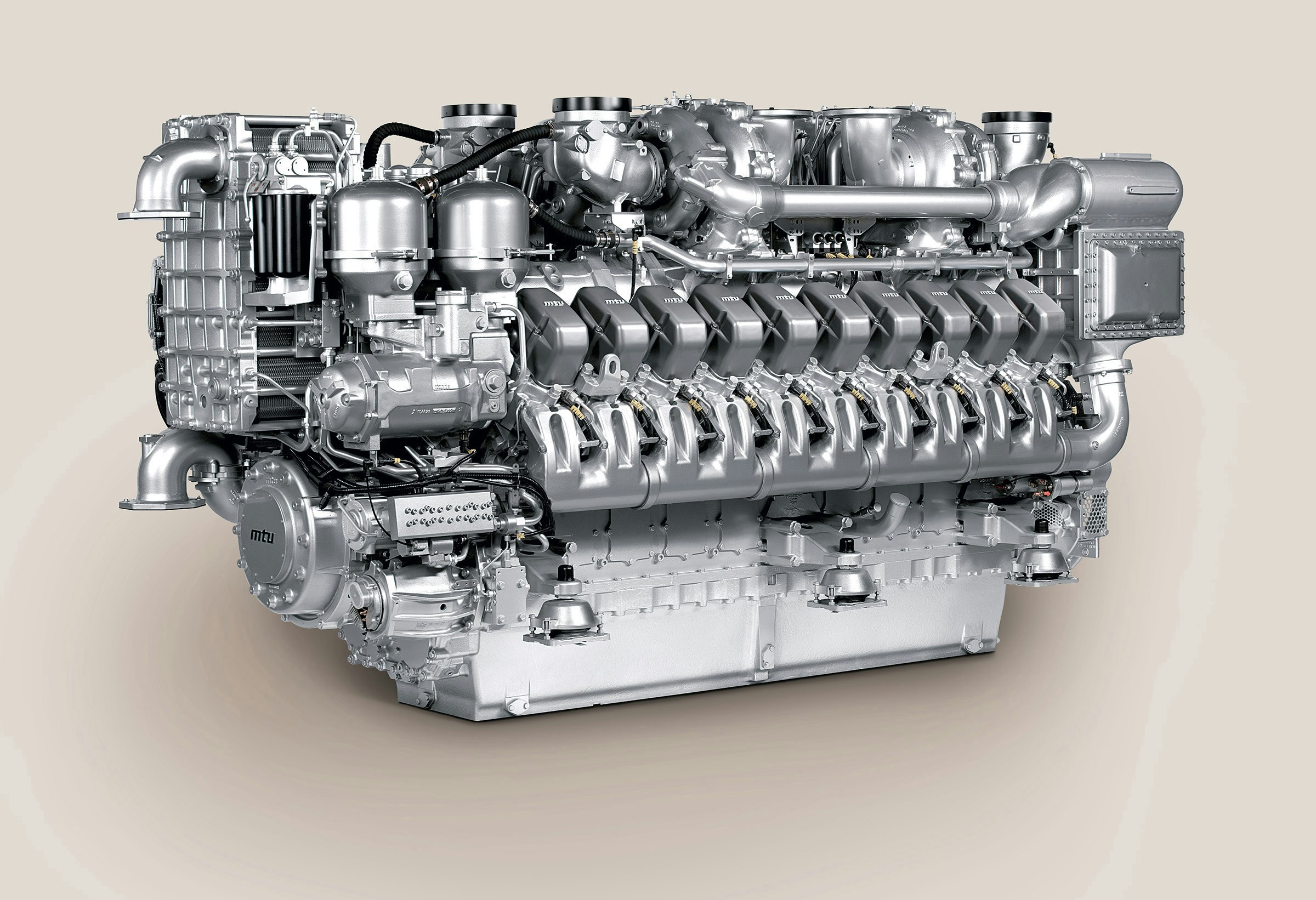

Rolls-Royce is to supply 18 MTU Series 4000 diesel generator sets to BAE Systems as part of the Power Improvement Project (PIP) to increase the resilience of the power and propulsion system in all six Type 45 destroyers.

The two existing diesel gensets are to be replaced by three MTU gensets per vessel. The three MTU gensets will complement two existing Rolls-Royce WR21 gas turbines also supplying power to the electric propulsion system.

Knut Müller, Head of MTU’s Marine & Government Business, said:

“We are delighted to have convinced our partners BAE Systems and the Royal Navy once again of the outstanding merits of our Series 4000 gensets and engines. I am convinced the Royal Navy will benefit from this long-term – also thanks to the simplified logistics when it comes to maintaining our engines.”

Jon Pearson, Warship Support Director, BAE Systems, said:

“PIP is set to deliver a significant improvement in the performance and reliability of the Type 45 destroyers. It will be carried out by Cammell Laird and BMT, led by BAE Systems and relying on the excellence of our supply chain partners such as MTU and Rolls-Royce to deliver a high quality, timely and cost effective solution for the Royal Navy.”

In 2015, the Ministry of Defence acknowledged that the vessels propulsion system, specifically, the Northrup Grumman intercooler was experiencing reliability issues, previously reported as nothing more than “teething troubles”.

A staggered refit was also announced, which will involve cutting into the ships’ hulls and fitting additional diesel generation capacity, this has become known as Project Napier.

According to the Royal Institute of Naval Architects:

“Project Napier was established in 2014 with two core work strands. The first of these, known as the Equipment Improvement Plan (EIP), is continuing efforts to enhance system reliability and to meet the original design intent in the near term.

The second component of Project Napier is a longer term Power Improvement Plan (PIP), intended to improve overall system resilience by adding upgraded diesel generators to provide the electrical generation capacity required to meet the overwhelming majority of propulsion and ship power requirements without reliance on WR-21.”

Project Napier will cost £280 million.

The reliability issues with the intercooler lead to occasional near-complete power generation failures, temporarily disabling not only propulsion, but power generation for weapons, navigational systems, and other purposes, leaving the ships vulnerable to “total electric failure”.

HMS Daring’s engines failed in the mid-Atlantic in 2010 and had to be repaired in Canada, with further repairs for engine failure in 2012 in Bahrain after it encountered propulsion problems while on patrol off the coast of Kuwait.

Two years ago, Ministry of Defence officials admitted that the ships were breaking down because the intercooler could not cope with the warm waters of the Gulf.

Manufacturers of the fully functioning, non-problematic turbines Rolls Royce said that the intercoolers for the WR-21 had been built as specified, but that conditions in the Middle East were not “in line with these specs”.

The MoD said in a statement about this earlier in the year:

“The Type 45 was designed for world-wide operations, from sub-Arctic to extreme tropical environments, and continues to operate effectively in the Gulf and the South Atlantic all year round.”

Current First Sea Lord Admiral Philip Jones clarified:

“WR-21 gas turbines were designed in extreme hot weather conditions to what we call “gracefully degrade” in their performance, until you get to the point where it goes beyond the temperature at which they would operate… we found that the resilience of the diesel generators and the WR-21 in the ship at the moment was not degrading gracefully; it was degrading catastrophically, so that is what we have had to address.”

It should be noticed that despite the problems, the Royal Navy has been able to deploy Type 45 destroyers in nine-month cycles to the Gulf region where temperatures are high with little fault.

Still amazed that the IEP T45 in its original form generated less electric than the conventional Horizon.

£280 million!

The wrong decision was made and the cost to fix it, is the cost, though cookies.

What amazes me is just how slow this is taking, this needs to be urgently speed up, we can not have air defence escorts that can not be 100% relied on to defend whatever they are escorting. If there is any risk of them breaking down at the key moment, they are effectively useless in a war situation.

At over £40 mm a ship it does seem pretty extortionate, I’ve been trying to google the cost of the generators as they do supply them commercially to work out what % they make up of the overall cost. I know fitting them retro actively will be more expensive but surely not that expensive. I wonder how much the old one’s fetch on the used market.

BB85- all the type 45’s need to go into dry dock- have their steal hulls cut open and new generators inserted- then the hulls repaired and made good- that is the main cost- not the generator sets themselves.

I do think whilst in dry dock having hulls cut open that is the time to fit strike length mk41 vls cells- at least 12 if not more- some state 16 could be fitted aft near the funnels and another 12 cells forward either side of the viper vls air defence missile cells.

As sea captor can be quad packed into mk41 cells that could potentially give a vast increase in air defence load and offensive missile load (ASRCO, NSM, LRASM, Tomahawk) and make the type 45 really comparable to heavy destroyers in service in Japan, Korea, America and the type 55’s and 52 PLAN destroyers coming into service in ever increasing numbers.

Doesn’t Rolls Royce own a large part of MTU?

Yes, Which is why they are supplying them.

I saw a Fifth Gear TV Prog where they upgraded the intercooler on a Subaru car. They moved the intercooler from the top of the engine, where there was a problem with inlet air being too hot thanks to the engine, to behind the front bumper where the air was cooler. Just for good measure, they fitted a bigger intercooler while they were at it.

OK a rally car & a warship are very different, but could the same basic ideas be used? i.e. move the inlet to somewhere cooler & fit a bigger intercooler.

I think we need to get Fifth Gear onto this immediately, let them put in a bid competitively against Top Gear that should bring the price down. I’m sure Captain Clarkson and Commodore Hampster would be the perfect characters to put the updated ships through their paces too. Well apart from the inevitable 3rd World War I guess.

The issue they were encountering wasn’t the air temperature it was the temperature of the Ocean, warmer waters degraded the cooling potential.

There are a lot of intercoolers used in many applications, all around the world. Getting intercooler engineers to look at this, even if they are from other applications, might be the way to fix this problem.

James Burke in his Connections series back in the 1970s pointed out that many leaps forward came from someone spotting an existing idea & adapting it to a new use.

Right…the recouperator on a GT is nothing like an inter cooler that is fitted to a car.

It works at far higher temperatures nearing 1000 Deg C and much larger air volumes.

The exotic materials in the recouperator matrix degrade over time reducing the efficiency of the whole GT / recuperator system. On a T45 this “graceful degradation” was far quicker than the design had allowed for hence the issues with the GTs tripping.

The MTUs that will be fitted are bloody good maritime engines. Very efficient and very power dense they are used all over the world. So a big plus is that the chance of them becoming obsolete or not having support is very low.

Putting them into the ship will be interesting but not overly taxing. Yes holes will need to be cut in the hull but that is standard ship repair practise and nothing to get excited about. Replacing 2 for 3 will give a good extra power margin on the vessel and will allow the ship to run , during normal cruising, on DGs instead of GTs if required.

So going back to basic engineering, if your existing intercooler/whatever is not doing the job of cooling, then surely you look at fitting a bigger one that will.

Nope…the intercooler matrix material degrading and its detrimental effect on the whole recouperator systems performance was the issue…not the size of the intercooler /recouperator.

The part in question is really not that big or anything particularly impressive to look at. However it was made by Northrop Grumman and because it is a US Company it has ITAR issues associated with it which added a whole other level of aggravation to getting it fixed. A new modded intercooler is at sea on a T45 and I am told is performing well.

The workarounds on the Engine control Software and IEP system have helped as well and the new DG sets will add an extra level of reliability.

I read recently that HMS Defender had new gas turbines installed. Are the intercoolers of these new gas turbines fitted to HMS Defender flaw-free, thus obviating the power improvement plan, or is the scope of adding redesigned intercoolers to the new turbines unfeasible, thus requiring the power improvement plan to solve the problem?

The gas turbine recuperator does not function in the same way as an intercooler. The intercooler is used to reduce the temperature of the air entering the engine that has been compressed by either a supercharger or turbocharger. Thus by cooling the compressed air before it enters the engine more fuel can be used to gain more power.

The recuperator uses waste exhaust heat to INCREASE the air temperature before it enters the compressor stages. This sounds counterintuitive but for gas turbines by heater the inlet air means that less fuel is required to heat it up compressed air in the burners thus increasing overall efficiency not power. The recuperator is used in all gas fired power stations for this very reason to reduce the amount of fuel required to attain a given level of power.

The T45s problem as I understand it is that it uses sea water for cooling the recuperator and the warmer temperatures cause it to fail quicker than expected. Most power station either have access to rivers, coolant ponds or use refrigeration. I am surprised that the T45s do not use refrigeration to cool the recuperator as that gives the most efficient benefit.

So in other words a fix is possible, if the will was there.

I must admit I was daydreaming on where to get cooler water. I wonder how deep in tropical waters, you have to go before you get a measurable drop in temperature. Think of a reverse periscope or snorkel. If a telescoping pipe could be extended 5 to 8 metres below the hull, would the water it pumps up, be that bit cooler?

Obviously, said fantasy pipe would be retracted when not needed.

I do feel sorry for the T45. It is a nearly ship, always robbed when money is needed elsewhere. Hence the cut from 12 to 8, then 6. No 155mm or 127 gun, having to make do with the old 114mm. No CEC. Second hand elderly Harpoons rather than new anti ship missiles. No ABM upgrade so far. The option of Mk41 vertical launcher for Tomahawk passed up. Not a happy history so far.

Thanks for the explanation, I wasn’t aware of the difference!

Like you, I am a bit confused why they aren’t solving the root problem with the recuperator, rather than accounting for it with more backup power… I’m all for fitting the gen-sets regardless to be honest, for future proofing, but just fit the turbine too. No one wants a catastrophic failure of the primary power system, even if there is sufficient back up.

IIRC the recuperator is one of the American parts of the original UK-US joint project. There may be issues with the IP, or perhaps ITAR problems. Or maybe it’s just easier to increase the diesel power.