There’s a lot of misunderstanding and myth circulating about how many ships the shipyards in Scotland are expecting to build, but what’s the truth?

The chopping and changing when it comes to the requirements of the Royal Navy in terms of ship classes, numbers and even the building of those ships has caused a great deal of misunderstanding and confusion, not least when discussing Scottish politics.

Shipbuilding on the Clyde became controversial during the 2014 Scottish Independence Referendum, when the pro-union ‘Better Together’ campaign touted the planned Royal Navy order of 13 Type 26 Frigates to be built on the Clyde as a benefit of Scotland remaining in the United Kingdom.

Essentially, people believe that Scotland was promised 13 warships.

The issue? The future composition of the Royal Navy surface fleet was changed after a defence review in 2015 resulting in five of those frigates being cancelled and replaced with cheaper general purpose vessels, amid cries of ‘betrayal’ but why did this happen?

It isn’t that simple though, let’s look at why.

Why were Type 26 numbers reduced?

The initial Type 26 Frigate order had been cut back from 13 to 8 in order to fund more of the immediate spending outlined in the 2015 Strategic Defence and Security Review. As a result of Type 26 being reduced to 8 ships, it was announced that five cheaper general purpose frigates were to be designed and ordered.

Part of the reason for this is that the MoD is hoping to reduce its reliance on BAE and cut the costs of procurement by spreading shipbuilding work across civil and naval yards around the UK. To this end, the UK Government say they are implementing the results of an independent report into the National Shipbuilding Strategy by Sir John Parker which recommended that the Type 31 Frigate build be spread across the UK, with blocks and components being constructed in yards in both Scotland and England.

The National Shipbuilding Strategy was intended to be a “radical, fundamental re-appraisal of how we undertake the shipbuilding enterprise in the UK, intending to place UK naval shipbuilding on a sustainable long term footing”.

The news that BAE decided not to bid to assemble the Type 31e Frigate on the Clyde due to an apparent lack of interest created a stir in Scotland after earlier expectations that the light frigates would be built there.

However, BAE themselves say that shipbuilding capacity on the Clyde will be maxed out until the mid 2030s while the Ministry of Defence want the first of the new Type 31 Frigates in service by 2023, one of the primary reasons they have decided not to bid as prime contractor for the project, there’s no space at the BAE yards on the Clyde to do so if they are to meet the deadline for the first Type 31e to hit the water.

BAE say the move will allow them to ‘appropriately support the National Shipbuilding Strategy’ whilst ensuring the delivery of the five Offshore Patrol Vessels and the City class Type 26 frigates currently on contract, ‘to time, budget and to the highest quality standards.’

In a press release BAE say:

“BAE Systems is focused on the manufacture and delivery of the two QE Class carriers, the five River Class Offshore Patrol Vessels (OPV) and the first three City class Type 26 warships, as well as continuing to develop and upgrade combat management systems on all Royal Navy ships. Taking account our current and future workload, including Type 26, our shipbuilding capacity on the Clyde will be full until the mid 2030s.”

BAE also signalled their reluctance to bid for the Type 31 Frigate as prime contractor due to concerns of a “race to the bottom” on price. Speaking to The Herald here, BAE managing director Iain Stevenson signalled the defence firms lack of interest on building the vessel:

“We do want to be involved in Type 31. But we have questions. Does it have a budget? What are the timescales. We have not got solid facts. Type 31 could be a race to the bottom. If it is a front price contract people might bid for it to win and it and it might put them out of business. We would not, because we are BAE Systems.”

What about the Type 31 Frigate?

Babcock recently was recently chosen as preferred bidder for the new £1.25 billion Type 31 Frigate, the five vessels will be built in Rosyth.

What about other vessels like the new support ships?

The First Minister of Scotland previously stated that the international tendering for auxiliary vessel contracts, specifically the Fleet Solid Support Ship contracts, is a betrayal of the Clyde. This is however despite the yards having no interest in them, having never been promised them and the fact the vessels couldn’t physically fit on the slipway.

Sturgeon said the move was an “absolute betrayal” in light of promises made in the run-up to 2014’s independence vote. In fact, what was “promised” before the referendum was work on complex warships, like frigates and destroyers.

There are three key problems with this:

- The Clyde is at capacity with the River class and Type 26 Frigate builds and has no intention of bidding for this work.

- The 40,000 tonne support vessels wouldn’t physically fit on the slip alongside the Type 26 Frigate builds.

- The only vessels “promised” were warships, such as frigates and destroyers.

The unions and the UK Defence Journal have been advocating that the build stay in the UK, but the Clyde was never in line to build these ships.

We spoke to a contact at the yard who told us:

“This is the second time this news has popped up and I have no idea why the government in Edinburgh are making these claims, these vessels were not promised to us and they’re not warships. We’re busy with the last batch of River class ships and the first batch of the City class ships. If I had one message for them, it would be to stop using us a political football, we’re sick of it.”

We also spoke to Stuart Crawford, a retired regular officer in the Royal Tank Regiment and a former SNP defence spokesman. Crawford said:

“Nicola Sturgeon declared that the international tendering process was “a blatant betrayal of Scottish shipyards” and a reneging of promises made to the Clyde shipyards at the time of the Scottish independence referendum in 2014. Other SNP politicians have been quick to jump on the bandwagon, including Humza Yousaf MSP, Minister for Transport and representing a Glasgow constituency. The problem with the ‘Clyde betrayal theme’ is that it is just not based on the evidence. As outlined in the UK Defence Journal, three main facts undermine the argument.

First, the Clyde is already at capacity building the Offshore Patrol Boats and Type 26 frigates that will keep it busy until at least 2030. There is no intention by the Clyde yards to bid for the work in any case. Second, the FSS ships, at a projected size of 40,000 tonnes each, just wouldn’t fit into the existing Clyde facilities. And third, the only ‘promise’ that might possibly have been made relates to complex warships only, of which the Clyde currently has it fill.”

What’s actually happening on the Clyde, is it a ‘betrayal’?

We asked Paul Sweeney, former Member of Parliament for Glasgow North East and a former yard worker at the BAE facilities on the Clyde.

“It is frankly bizarre that Scottish nationalists insist on trying to exploit a line of argument that Clyde shipyard workers have been somehow betrayed when they have job security until the 2030s with the current naval shipbuilding programme. Yes the Type 26 programme was rescoped from thirteen vessels to eight, but that change fails to take into account the additional order of five River Class Batch 2 Offshore Patrol Vessels that were placed on the Clyde to bridge work from the Queen Elizabeth Aircraft Carrier build – the largest naval ships ever built on the Clyde – and the commencement of the Type 26 Frigates, the second of which – Cardiff – will cut steel at Govan this week.

It also doesn’t take into account the significant overseas success of Type 26, with both Australia and Canada selecting the Type 26 for their own domestic frigate programmes against Spanish, Italian and Dutch rivals. This means the Glasgow-based Type 26 is now a global design, with significant involvement of the over one thousand engineering staff in Glasgow on those projects, as well as common purchasing from UK-based suppliers, even though the ships will be constructed in Adelaide and Halifax respectively, as is the norm for any advanced industrial country building ships for its navy.

It also doesn’t take into account that the pace of the Type 26 programme has been slowed from a 12 month drumbeat to an 18 month drumbeat, this extending the overall duration of the shipbuilding programme well into the 2030s. It also doesn’t factor in the opportunity of the five planned Type 31e lighter frigates, which will involve Glasgow-based BAE engineers and also construction and assembly at either Ferguson Marine or Rosyth in Fife, with BAE workers likely seconded to support those builds as happened with the aircraft carrier assembly.”

Let’s get to the point, what has been built in Scotland as a whole since 2014 and what are the yards planning on building in future?

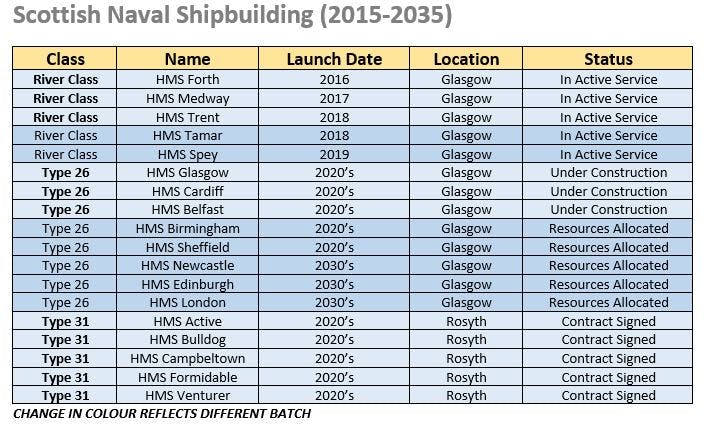

So, what does the prospective order-book BAE are talking about actually look like for the next few decades? We’ve included the contracted and non-contracted work the Clyde is expected to build to give an idea of the scale of work already present as BAE cite this as a reason for not bidding for the Type 31e to be assembled on the Clyde.

18 ships of three types, excluding the two aircraft carriers, have been or will be launched from Scottish yards between 2014 and the 2030’s.

Ordering in batches is common for projects of this size around the world and was last seen with the Royal Navy for the Type 45 Destroyers and recent Offshore Patrol Vessels. The Type 45s first batch order was for three vessels. Ordering this way allows for changes to specifications and allows for refinements to contracts as working practices evolve and efficiencies are learned.

Eight Type 26 Frigates are to be built in total by their designers BAE, the contract for the second batch will be negotiated very soon.

Why have we included it despite this?

There are no other yards in the UK to build the Type 26, it’s a BAE product and their only surface shipyards are in Glasgow. The ships are not going anywhere unless the Royal Navy take the incredibly unlikely decision not to replace their frigate fleet.

The UK Government committed to eight advanced anti-submarine warfare ships in its 2015 Strategic Defence and Security Review (SDSR). The Type 26 programme currently employs more than 1,200 people in the UK supply chain, with a number of contracts already in place for the manufacture of major equipment for the first three ships. In total, there are already 33 UK and international companies working in the supply chain to deliver the Type 26 ships.

I don’t really comment on any of the UKDJ threads … BUT !

All this Type 26\31… What’s being built and where stuff is just dragging on too long!

Lets have a the Type 31 design flipping chosen for gods sake….

All shipbuilders in UK get to build one ASAP.

Job done.

the battleship drednaught was built in portsmouth within a year. the clyde yards, with modern technology should be told the expectation is for two ships minimum to be delivered per year

The UKDJ seems to have a bee in their bonnet about this.

Groundhog day

i just want to know where the details concerning the t 31e will come out.

This is a long article to say that instead of the 13 Type 26 frigates that were promised to BAE on the Clyde, 8 ASW and 5 GPFF, for a total tonnage of 8 x 7,600 + 5 x 6,500 = 93,300 tonnes, BAE on the Clyde have got 8 x 7,600 + 5 x 2,000 = 70,800 tonnes. That’s a reduction of nearly 25% in terms of tonnage. 5 x OPVs also have far less complexity than 5 x GPFF.

And BAE themselves stated in the past that workers were sent down to Barrow because there wasn’t enough work on the OPVs to keep them, and then later that the T26 build would be delayed because there weren’t enough workers left for such a complex warship. Also that apprentices weren’t being taken because of the shortage of work.

8 x ASW-FF + 5 OPV does not equal 8 x ASW-FF + 5 x GPFF, no matter how anyone tries to read the tea leaves.

Whether it’s correct or not to give less work to BAE itself is totally another argument.

It’s also to do with the hull. The original intention was to use the T26 holl, not just for the ASW but for the GP frigates. That has changed and only 8 of those hulls will be built, if the order actually survives beyond the first batch of 3. Some fear there might only be those 3, some that only another 3 will be built for a total of 6.

At this stage nobosy can say that “Eight Type 26 Frigates are to be built in total ” because there are no firm orders for the further 5. And as far as I know, for instance, there are no advance orders yet for the next 5 rebreathing low infra-red exhaust systems from Canada, whereas the 3 for the first batch were ordered a couple of years ago. I stand to be corrected on that if I missed the news.

Why are UKDJ playing the Scot Nats game ? They act as though their voters are barely literate, inbred, mouth breathers who will believe anything they tell them. Since they’re far and away the most popular party up there I bow to their superior knowledge. For the rest of us I’d recommend you try what works for me. When ever I hear the never ending, self pitying whine just blank it out !

the whole clyde subject is a sop to the SNP and the unions. they should be grateful for even getting the contracts

“Ordering in batches is common for projects of this size around the world and was last seen with the Royal Navy for the Type 45 Destroyers”

Yes, precisely. The T45 was originally going to be 12 of, dropped to 8 of, and only 6 were built.

Why is this writer keep insisting that 8 Type 26s will be built when only 3 have been ordered?

Relying on the word of governments is a risky business. See Brexit.

I’m sorry I just find it ridiculous, that we ended up spending 230million a year in overpriced and not really wanted make work (which no matter how you polish the turd is what they OPVs are) is just repressible levels of incompetence on the part of the MOD ( in this I’m blaming the political leadership and not the civil servants). What makes it worse is that a few years later we end up cutting the order of high end warships and replace them with whole newly designed ( add more wasted money) class of not quite what the navy wanted constabulary ships.

Forgive me for being a we bit grumpy but if the idiots we voted for had actual ordered the ships we needed in the right timeframe to get them built within the contracted work schedules we might not have ended up paying hundreds opon hundreds of millions for policing vessels when our navy is terminally short of high end escorts.

This is so much worse than I had thought. The strategy for maintaining naval ship design and build capability in the U.K. is just to pay BAE £230 M a year. If the work isn’t that cost then pay and no need to maintain capability.

The second strategy, while maintaining the first, is to pay others for building ships. I like the Babcock team offer but it is a Danish ship with French systems and possibly USA controlled technology (the article is not clear).

I do not blame politicians, not for the first strategy – the money is there. The Admirals had it to spend but faffed about (substitute your clause) with armchair wish lists for the Type 26. It was not delayed by cash flow, there was £230 M to start build.

I think the 15 year TOBA was quite sensible, to preserve and perhaps rescue shipbuilding in the UK. The idea would be to encourage BAE to invest, with a certainty of that cost being covered. Perhaps the contract wasn’t well written though, as BAE didn’t build the £200m “frigate factor” capable of building 2 frigates a year, then didn’t invest the £100m they said they would after that didn’t happen.

On the other hand there were delays with the T26 design, much to do with the hull design from what I heard – the aim being to make the T26 the best and quietest ASW in the world. So you can’t balme BAE either for not investing, particualrly after the Parker review saying shipbuilding should be shared around the UK. I guess the T31 design is because the basic T26 design, hull in other words, would be too advanced and expensive for a relatively cheap GPFF.

Then again, Parker is right, so you have conflicting strategies where you can’t actually blame anybody I guess, it’s one of those things that happens. And as some experts have pointed out, the whole strategy was a case of moving on from the so-called end of the Cold War into the modern era.

Hopefully it’ll all come out in the “wash” 🙂

Paul the bottom line is ( or should be ) the minister of state is responsible and accountable. We really need to start holding our political classes responcible for their actions or lack of action and not just let them float around in a haze of underperformance going from job to job.

“Doesn’t the UK build ships overseas anyway?

Many have misconstrued the building of a naval tanker in South Korea for the RFA as a break in this policy, that is not the case. Support vessels like this are eligible to be constructed outside the UK as only ‘complex warship’ construction (such as destroyers and frigates as outlined above) must stay within UK borders. Besides, no UK yard bid for the work.

RFA Tidespring

Other than procurement activity undertaken during the World Wars, the UK has not had a complex warship built outside of the UK since the start of the 20th century at least. All of the Royal Navy’s new complex warships are being built in UK shipyards and the UK Government says it remains committed to utilising the strengths of UK industry in this specialist and complex area.”

There was a break in policy with military warship like ships. During the labour years, the argument came up over the UK Industry/MoD alliance partnership for the tankers back in 2005-06-07etc… Andrew Tyler was one 6 figured paid individual who helped change this policy because of eu rules! Despite all the arguments since, in which we had the debate over warship-like and military and taxpayer-funded ships, this eu empire won the day and forget all the articles about 3.. and 3…, it was largely due to this eu and UK governments feeling obliged to obey for face/price value (to get out of it) even though it makes no sense (why would any sane UK Government come up with an independent policy like this?)! When was the last RFA Tanker built abroad? Argus was a conversion and the Point where farcical PFI ships owned by a private firm (Foreland Shipping) in which, yep a German yard benefitted mostly. Go back in history to 1970 see how many ships, or in particular tankers were built abroad!

No yard bid for this work? Well, Alan Dickenson wished to see Pallion involved in the MARs ships contract early on, the late Japp Krose of Swan Hunters had interest and also KOFAC for Barrow who gave the abilities of Barrow and how suitable Barrow was for building these ships and why they should be built at Barrow, but Barrow is owned by the great non-shipbuilder, shipbuilder BAE. But As I said before, all UK potential was pushed out by a policy adopted by its own treasonous UK governments who had no interest in manufacturing back then, including the labour governments. That’s why there were no UK bids! Nothing to do with capacity and the such.

“Committed to utilising the UK industry in this specialist and complex area” Wha is that? Just vested interests? The creative sector whatever that is? Electronics, fair enough, but not the house itself? Whativil Servants and politicians do not realise are that we have strength in shipbuilding as a whole and are pretty good at it, but it is only seen as metal bashing. Shameful and so wrong.

“Besides, no UK yard bid for the work.”

The problem with that Darren is it costs money to actually bid for a contract, and knowing that the likes of South Korea would be lower and their bid taken, I personally wouldn’t waste my shipyard’s time and money on a bid if I had one, and I daresay they thought the same.

It would have been cheaper for Canada to build their ships in Korea too, and the U.S.A., and Germany, and France, and Italy, but they don’t. We shouldn’t either. What they realize is it is much more important to keep their own shipbuilding/steel making industries going with work, keep the money in their own countries and keep their own people in highly, skilled well paid jobs.

Agree that British shipbuilding (and British heavy industry in general) has been intentionally run down in terms of both capacity and facilities through a deliberate lack of support which has not occurred in other countries.

It is time to end the decades long war against British heavy industry and start investing in, and supporting it, modernizing our facilities with state of the art equipment to maximize our efficiency and competitiveness.

Exactly my argument! When you know vested interests are going to scupper you, why to bother even though it makes sense to build here. This is a terrible situation.

but we’re britain, too snobbish to let shipbuilders build ships for us. just like we won’t buy foreign even when it makes fiscal sense we keep building pointless opv’s and then say we’ll decommission some of the ones we already have.upgrading the rivers to light frigate corvette is another area where we can moan about not having enough ships while getting rid of the ones we have.its not the politicians, it just bad management and clarity of thought at the m.o.d i’m intruiged by the new damen corvettes 1o meters longer than a river 5 knots faster, 20 more crew, yet comes with a 76mm gun, two triple asw torpedo launchers,two quad anti air missile launchers. we should be fitting out the rivers to these specs, already a popular export design, calling them light frigates or corvettes. the best thing is that THEY ARE ALREADY BUILT! there 9 more ships for the cost of refitting and configuring some of the ones we already have. i an armchair admiral like mecan come up with stuff like this why not the m.o.d?

I certainly don’t disagree with the last paragraph.

So how do you guarantee that happens. You can’t do that by placing an order alone. I work with UK manufacturing companies and there’s good and bad. The best, all with workers are on-board with the management they are agile they change there working practices to suit what they need to deliver, they reskill and re-equip themselves. And I have to say they don’t mind competition in fact they relish it. The worst plod on, same old inefficiencies, old kit. workers refuse to change, the management refuse to change. Companies like this would love a government contract handed to them no strings attached, they can just plod on same as they always have done.

I certainly don’t see a war on industry.

But why’s its government job to invest? BAe have had TOBA paid dividends to share holders. For 230m Bae have delivered the bare bones they had to and pocketed the rest. BAe have been uninspired by the type 31 competition, they complained about it. Look at other companies Cammell Liard, Babcock and other have relished it and have been making very positive statements.

SADLY OUR GOVERNMENTS HAVE BLINKERS WHICH ONLY ALLOW THEM TO SEE THE LATEST OVERPRICED TIMESCALE UNDELIVERABLE PIECE OF JUNK THAT BAE offers up.

The outlook is bleak. We have the Type 26 contract but it’s expensive and missing some fundamentals (anti-submarine weapons, something to go in the VLS). That said, it is a good design and has won the favour of Australia. However it is clear that the RN blames BAe for everything. BAe has put its system expertise behind the Camell Laird T31e but I can’t see any BAe involvement being accepted.

Babcock and BMT have floated a few designs but for a full build proposal they have adapted a Danish and French systems. They have accepted they don’t have the complex warship skills that BAe is paid to maintain. The Team 31 has space and systems to plug in all the options the MoD wanted. But there was no base fit and everything comes at a price. I think it likely we will get just a 76 mm gun to look like a warship and an “initial” batch of 3. This may not, probably will not, happen in time to replace maintain numbers as the T23’s go out of service.

I think thr MoD will go back to BAe for a second batch of T26 but the TOBA will end and full design capability will be shut down.

Bleak.

I think as with air domain the government will keep the design teams alive with concepts, we’re not building a 6th gen fighter yet but we’ve kept the know how through proof of concepts like Taranis.

BAe has hardly taxed their design team with the Leander, just stretched an existing design. Was TOBA there to keep the design team going? If it was then what have they been doing since the Type 26 design was baselined? Perhaps working on the Canadian and Australian design variations and if so will the treasury get something back from BAe?

The next stage of the process the T31 teams will be given funds to develop designs the MoD need to be clever and insist on full tech transfer of the Danish design in this phase and full ownership of the design, so any future export competition for the class is run by Team 31.

I hope if Babcock win BAe will see the benefit in participating and offer CMS at reasonable price knowing that there could be significant upside through exports. But its BAe…

I look at what Arrowhead 140 is spec’d at as just a public communication of what can be done for £250M, either for RN or for export. It basically says we can meet the RN’s target and also have a viable and competitive export option. We don’t know what has privately been submitted to MoD. Thales can still be the electronics lead integrator using BAe CMS and Artisan, presuming RN wants to maintain that commonality and BAe can’t suddenly inflate their prices without creating major political issues for themselves across their whole defence business with MoD.

another thing about BMT. they never firm up cost. or how long delivery would take per vessel.

Look how big the yard is behind that OPV.

there’s another big one at barrow where the t45 was built.

T45 was built at Govan, all 6 of them, then finished at Scotstoun across the way.

Daring was built in Scotstoun, the rest were built in Govan!

All 12 WERE to have been built in Barrow but BAE changed their mind and concenreated with the Astute programme.

Weaponless OPVs, the Russians must be laughing

Eight T26 ships should have been two batches of four ships each.

And if work was running out and the UK is contractually committed to spending £230 million a year, then why have we not started on a replacement for HMS Ocean.

In 2009 the Government signed a 15 year Terms of Business Agreement (TOBA) with BAE Systems and Babcock. The TOBA guaranteed BAE Systems a minimum level of surface ship build and support activity of £230 million a year.